SCT Ceramics Leverages the 3DEXPERIENCE Platform to Streamline Manufacturing Workflow

Advanced technical ceramics manufacturing company maximizes efficiencies by centralizing collaboration and leveraging real-time data management with SOLIDWORKS and the 3DEXPERIENCE platform.

Challenge

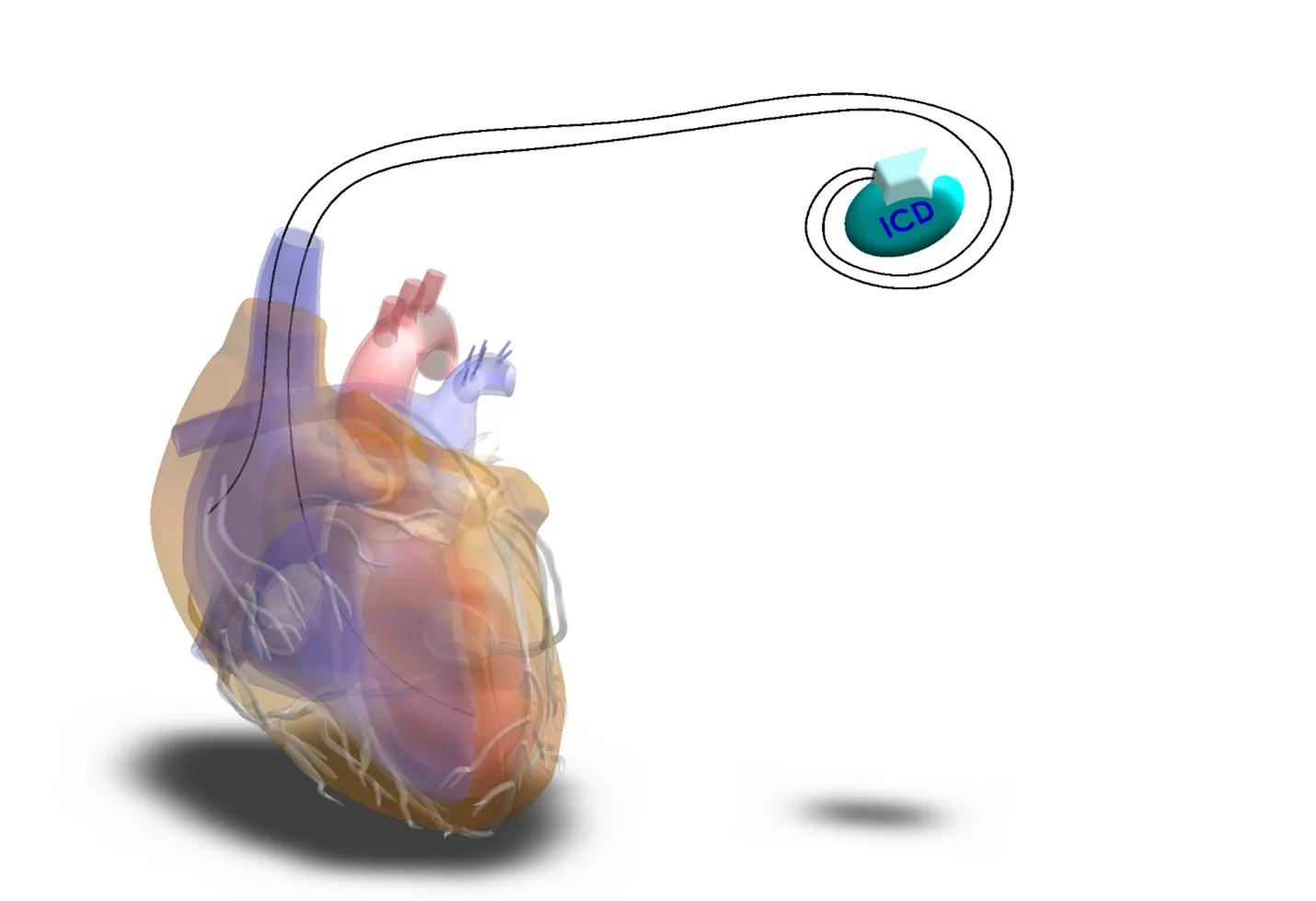

Develop the most advanced ceramic-to-metal brazing technology used for aerospace, medical device, and energy industries.

Solution

Implement modeling, design, data management, simulation, collaboration, and communication solutions from the 3DEXPERIENCE® Works portfolio, which operates on the cloud-based 3DEXPERIENCE platform.

Results

- Improve efficiency in the manufacturing process

- Fully connect data between research, development, and production

- Reduce errors while accelerating the production cycle

- Ensure that every department works with the most current data

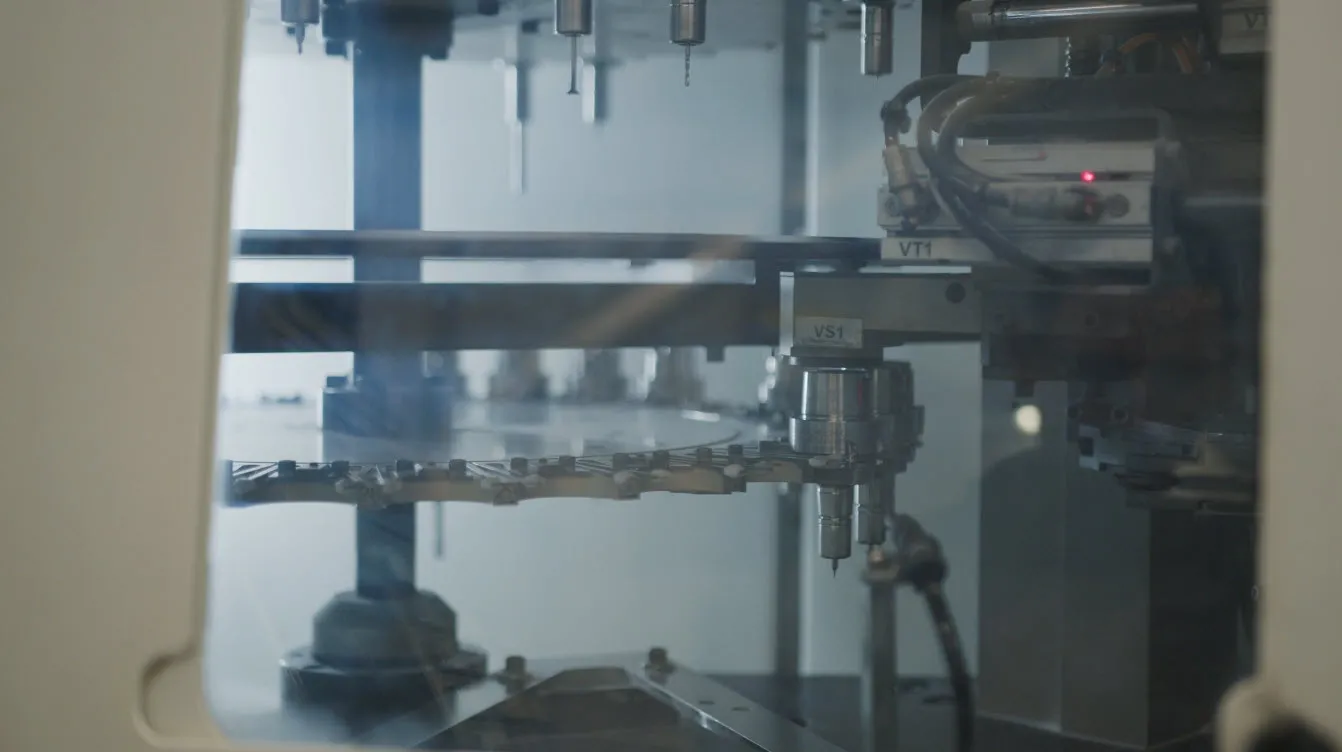

SCT Ceramics is a leader in advanced technical ceramics and ceramic-to-metal brazing technology. This process creates hermetic seals that ensure durability and reliability in the harshest environments for aerospace, medical device, and energy industries. Evolving from porcelain manufacturing to producing custom connectors and feedthroughs, the company thrives on anticipating market trends and delivering innovative solutions to meet the exacting standards of its clients.

SCT’s 200+ employees are dedicated to engineering and manufacturing excellence and acting as a partner in innovation alongside their customers, delivering components that enable groundbreaking advancements across several industries.

Improving the Process

SCT faced challenges in streamlining its internal processes and ensuring collaboration across departments. Traditional file storage systems lacked traceability, and inefficiencies in version management often led to setbacks in the development cycle.

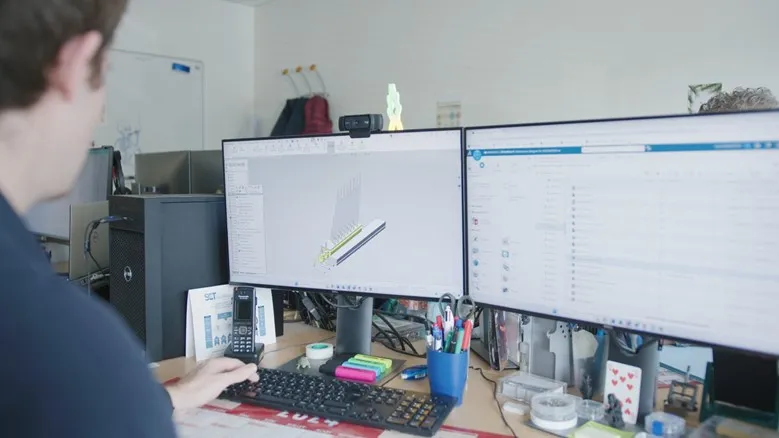

In a highly competitive market, the need for a cohesive, efficient solution became clear. “We were looking to improve the efficiency and robustness of our manufacturing processes,” explains General Manager Gilles Arnaud. “The 3DEXPERIENCE® platform and SOLIDWORKS® played a key role in achieving this goal.” The Dassault Systèmes’ solutions provided an end-to-end solution for design, collaboration, and life cycle management of their components.

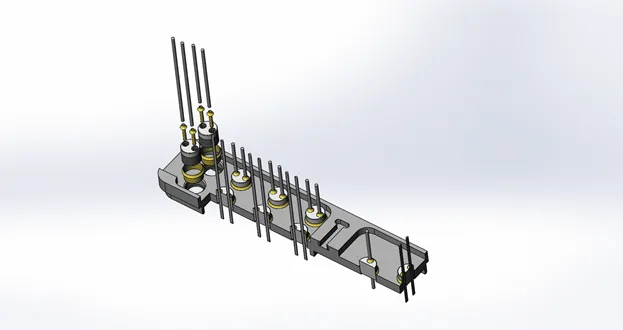

“I use the 3DEXPERIENCE platform daily. I do product modeling in SOLIDWORKS, developing new projects, and designing mechanical components,” says Engineering Project Manager Tom Demester. “And the platform helps us streamline our daily workflows.”

Related Resources

The 3DEXPERIENCE platform and SOLIDWORKS played a key role in achieving this goal. I use the 3DEXPERIENCE platform daily. I do product modeling in SOLIDWORKS, developing new projects, and designing mechanical components and the platform helps us streamline our daily workflows.

Real-time Data Management

Dassault Systèmes 3DEXPERIENCE platform also bridges the gap between research, development, and production teams. “The main advantage of the cloud is the traceability of file versions,” details Engineering Project Manager Benjamin Boniface. “The second advantage is we have completely decentralized managing our IT infrastructure.”

Boniface continues, “Today we work more efficiently, mainly because we are sure to have the latest, most up-to-date files, regardless of which department opens them.” This efficiency reduces errors and accelerates the production cycle while ensuring that every department works with the most current data.

Centralized Environment

A centralized computing and data management environment offers numerous advantages by simplifying access to information, fostering collaboration, and enhancing security. By reducing redundancy and providing a single source of truth, a centralized environment creates a more efficient, secure, and streamlined operation that effectively addresses the evolving demands of today’s forward-thinking enterprises.

With all data and applications housed in one location, teams can easily access the latest information, reducing the risk of duplication and ensuring all team members work on the most up-to-date files. “The 3DEXPERIENCE platform in three words? Customizations. Intuitiveness. Centralization.” enthuses Demester. “Centralization is a really important feature of this platform because it lets you find one tool for 3D modeling, another one for storing files, and another for searches, all in the same place, so you can find the right files right away every time.”

Boniface concludes: “I recommend the 3DEXPERIENCE platform to companies the size of SCT mainly for the robustness in parts life cycle management.”

Winning the Race to Market

SCT exemplifies how adopting innovative tools like the 3DEXPERIENCE platform can improve manufacturing processes. By enhancing collaboration, improving file management, and centralizing resources, SCT has positioned itself to meet the substantial demands of its innovative customers with precision and efficiency.

Products used:

- SOLIDWORKS 3D CAD

- Collaborative Designer for SOLIDWORKS

- Collaborative Industry Innovator

- DraftSight

- 3DSwymer

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.