Seats, Inc. Drives Innovation with Simulation Solutions

Seat manufacturer reduces design errors and the need for prototypes while optimizing critical manufacturing processes with SOLIDWORKS and 3DEXPERIENCE Works Simulation.

Results

- Replaced costly prototype iterations with less costly simulation iterations

- Reduced errors to less than 1 percent

- Optimized weld locations and reduced number of welds required

- Drove innovation in seat/part design with advanced simulation and topology optimization

Solution

Replace Solid Edge CAD and Ansys simulation tools with integrated SOLIDWORKS modeling, design, simulation, product data management(PDM), documentation, and inspection solutions; then add advanced 3DEXPERIENCEWorks SIMULIA simulation solutions to take advantage of more affordable cloud computing.

Challenge

Leverage simulation technology to drive innovation in seat design in a more flexible, integrated, and cost-effective manner.

Seats, Inc. is a leading manufacturer of seating and accessories for wheeled or tracked vehicle operators. Founded by W. R. Sauey in 1952, the company has grown to become one of the most comprehensive seating manufacturers in the United States. The company produces standard and custom seats for any vehicle other than aircraft and automobiles. Headquartered in Reedsburg, Wisconsin, the company operates manufacturing facilities across Wisconsin, Texas, Kansas, Iowa, and Mexico from a total footprint exceeding 400,000 square feet.

Until 2019, the company used Solid Edge® CAD software and ANSYS® simulation tools to develop and engineer its products. “We needed a more flexible, integrated design and simulation solution to increase efficiency and reduce costs,” recalls Director of Engineering Jesse Boyarski. “Our simulation needs run from basic linear static stress analysis to motion simulation to more complicated, nonlinear fatigue, contact, and plastic deformation analysis.”

Giving Integration the Best Seat in the House

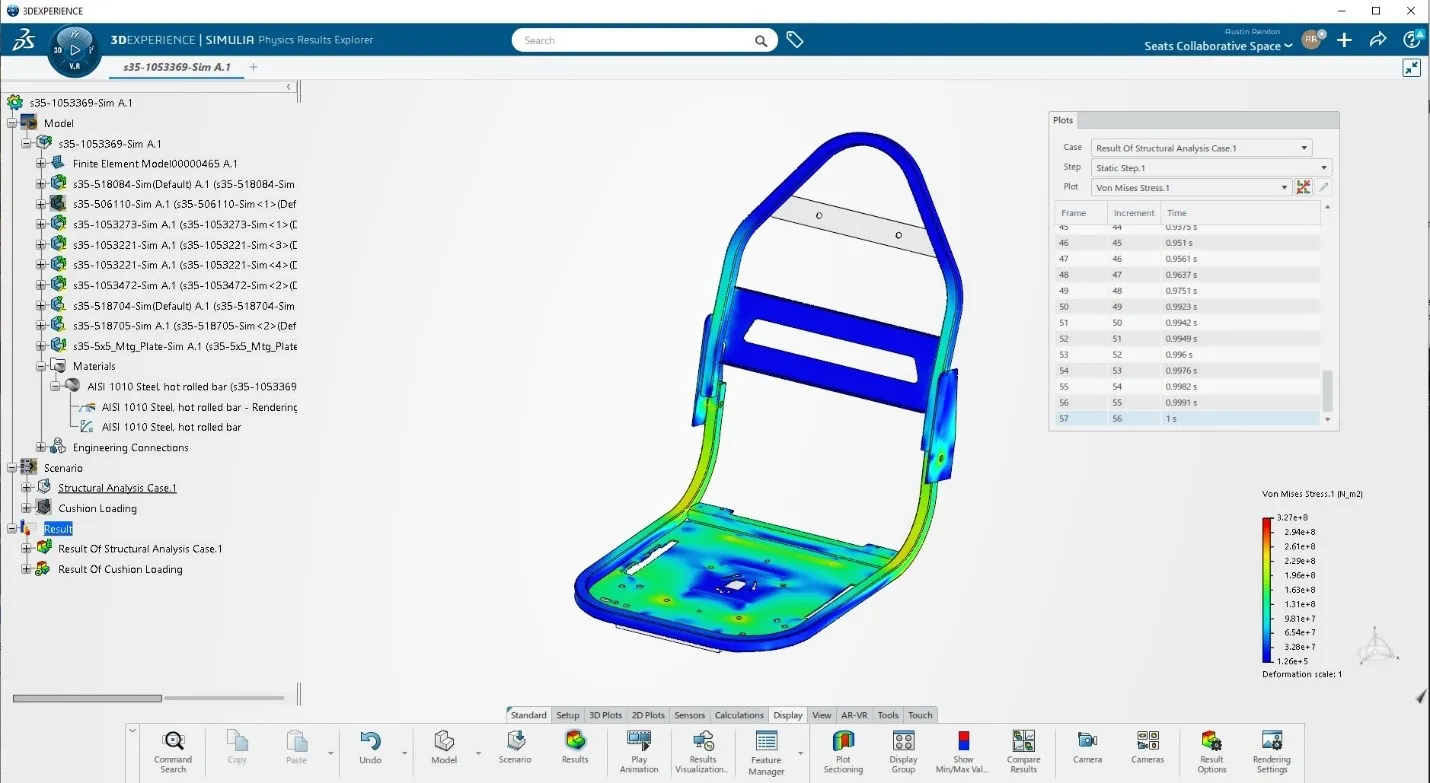

Many of Boyarski’s customers already used SOLIDWORKS, so in 2019 the company adopted the SOLIDWORKS integrated product development environment, along with 3DEXPERIENCE Works Simulation. “Designers can use integrated SOLIDWORKS simulation solutions to run basic simulations as they design, while power users can utilize 3DEXPERIENCE Works Simulation solutions for more complicated analyses,” Boyarski explains. “We are also very confident in our simulation results, as we’ve seen tight correlation with our physical testing results.”

Related Resources

The move to the SOLIDWORKS product development ecosystem and the addition of SIMULIA simulation solutions has enabled us to drive value in product design. With powerful integrated tools, we are developing the durable, reliable, and innovative seat features that our customers want while shortening design and testing cycles, maintaining high levels of quality, and keeping costs low."

Seats engineers also leverage PDM to improve product quality and reduce errors with built-in revision controls. “With everybody using SOLIDWORKS tools and our data managed by PDM, we’re seeing both time and cost benefits, as well as meeting critical ISO compliance requirements,” Boyarski stresses. “We are developing the durable, reliable, and innovative seat features that our customers want while shortening design and testing cycles, maintaining high levels of quality, and keeping costs low.”

Buckling Up for Simulation-Driven Design

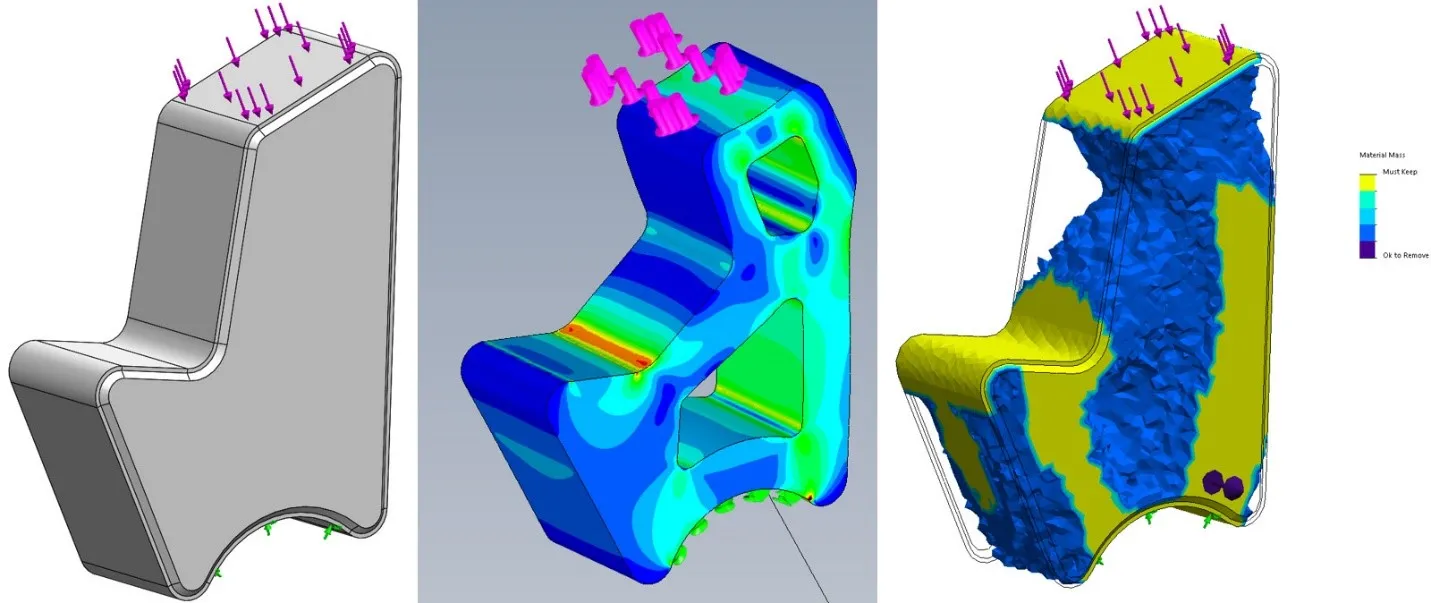

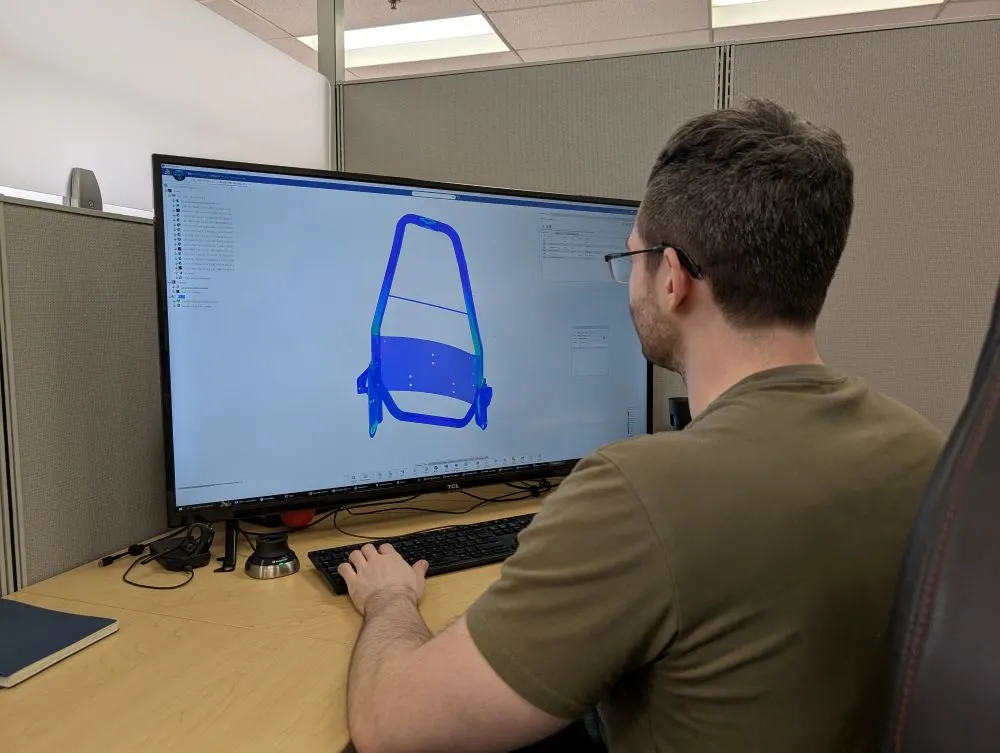

Seats can deploy simulation tools that are tailored to each function. Seats designers leverage basic linear static stress and motion analysis, and engineers tap into advanced analysis tools using the load results of motion analysis to run more complex simulations to validate innovations and final designs. “Being able to run a quick analysis while designing a part is extremely useful because you can make a change and rerun the simulation to see if the change addressed the issue,” enthuses Design Engineer Austin Rendon. “I’ve personally used SOLIDWORKS topology optimization to reduce material in powdered metal components and 3DEXPERIENCE Works Simulation to optimize weld locations, reducing the number of welds and material usage in a seat frame while maintaining the overall strength and stiffness.”

Products Used:

- SOLIDWORKS Standard CAD

- SOLIDWORKS Simulation Standard

- SOLIDWORKS Simulation Professional

- SOLIDWORKS Simulation Premium

- SOLIDWORKS PDM Professional

- SOLIDWORKS Composer

- SOLIDWORKS Inspection

- 3DEXPERIENCE Works SIMULIA Durability and Mechanics Engineer

- 3DEXPERIENCE Works SIMULIA Simulation Collaborator

- Collaborative Designer for SOLIDWORKS

- Collaborative Industry Innovator

- 3DEXPERIENCE Works Learner

- 3DSwymer

Learn More About 3DEXPERIENCE Works and SOLIDWORKS

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.