Trident Builds Smarter Hydraulic Solutions

Machinery manufacturing company leverages customer-driven innovation model and SOLIDWORKS to build optimal hydraulic solutions for a wide range of industries.

Challenge

To push the boundaries of performance and innovation for hydraulic system design and system integration across many industries, including waste management, automation, and heavy machinery.

Solution

Implement SOLIDWORKS Design and Visualize tools to design and manufacture complete, detailed parts from design to release, which includes analyzing forces, confirming tolerances, and reducing the risk of failure in a virtual environment to deliver top quality solutions.

Results

- Validate designs to ensure tolerances before production

- Verify product for reliability and safety under high loads

- Communicate ideas effectively to demonstrate system functionality

- Streamline the design from concept to final production model

Trident Hydraulics has been a leader in bespoke hydraulic system design and system integration for over two decades. Headquartered in the UK, the company has built a reputation for pushing the boundaries of performance and innovation while serving clients across industries including waste management, automation, and heavy machinery.

From its earliest days Trident embraced SOLIDWORKS®, as company founder and CEO Mike Forester was an early adopter in 1999. “I’m just SOLIDWORKS through and through,” he notes. Since adopting SOLIDWORKS, the company has evolved from building standard hydraulic power packs to delivering cutting-edge servo control systems.

Great Design Ensures Success

Trident views product development as a joint venture with its customers. The team collaborates closely with clients right from the start of new projects to uncover system inefficiencies. “We visit the customer to find out what issues they’re facing, and we reverse-engineer improvements,” says Managing Director Michael Owen.

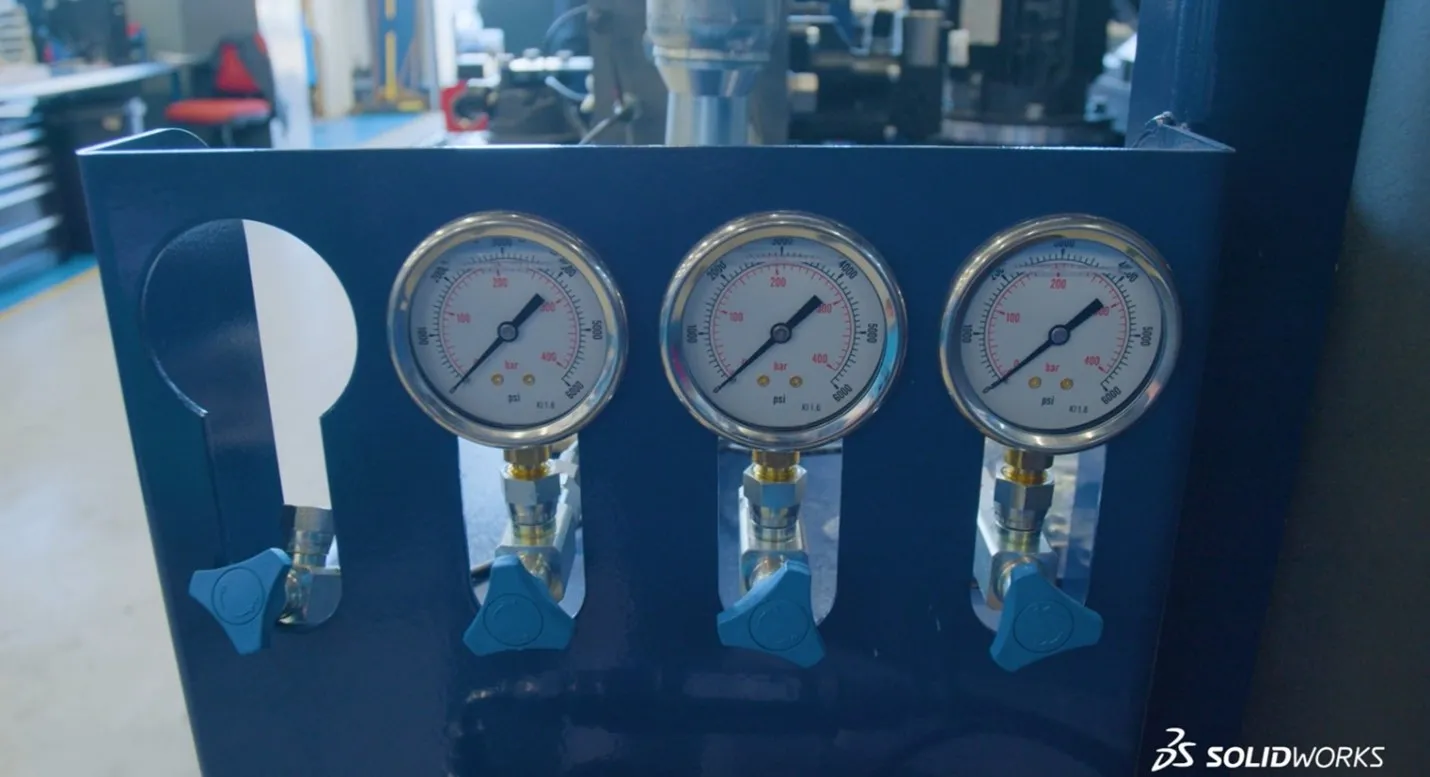

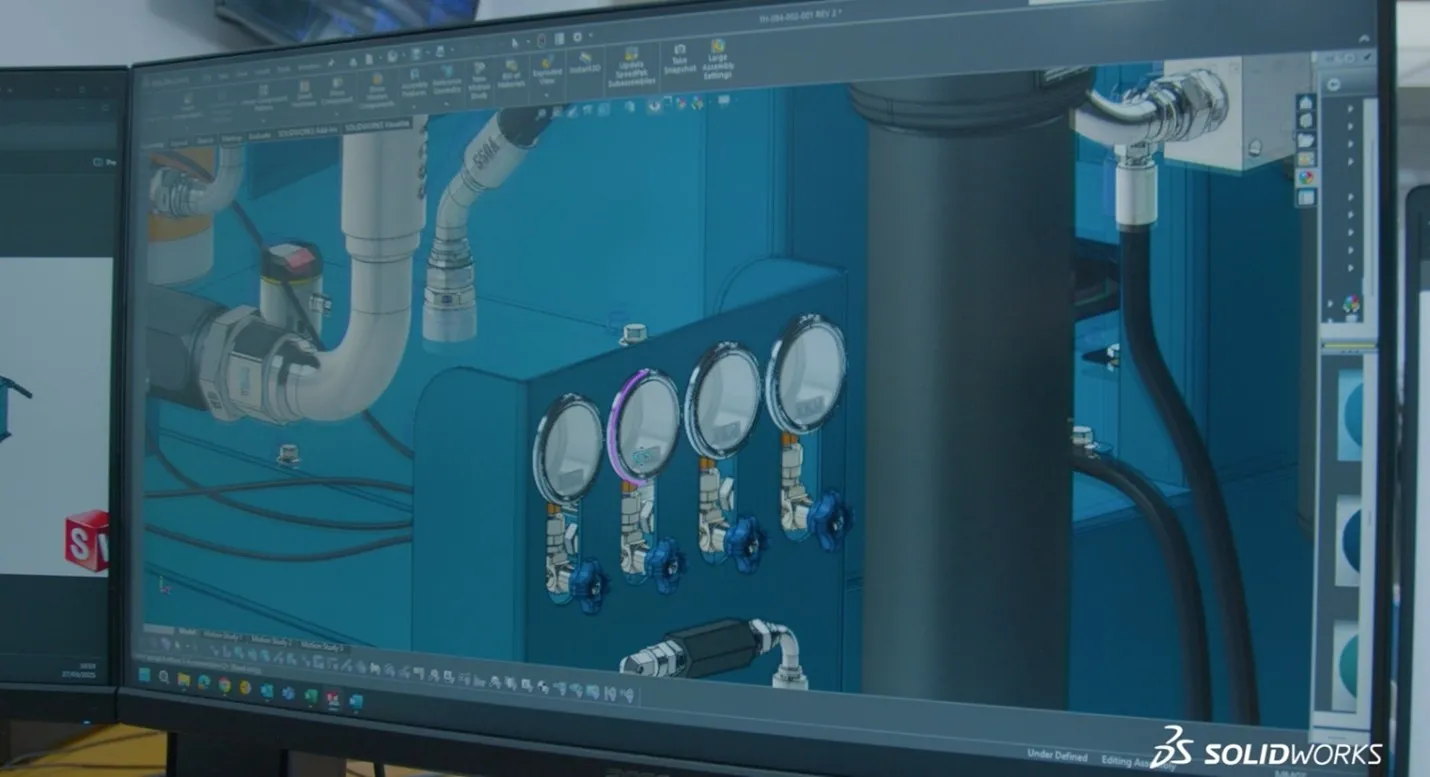

Once the engineering team understands the key issues, Trident engineers model all components, including pumps, manifolds, motors, and more, and digitally verify fit and function in SOLIDWORKS before a single part is manufactured. Considering the extreme pressures and flows typical in hydraulic systems, the ability to simulate and validate designs on the front end results in significantly more efficient product development on the back end.

Dassault Systèmes SOLIDWORKS enables the team to perform verification steps that ensure safety and reliability under high loads. Trident engineers go far above and beyond just designing parts. Analyzing forces, confirming tolerances, and reducing the risk of failure in a virtual environment help the Trident team confidently deliver high quality solutions to its customers every single time.

Related Resources

There are comparable tools out there, but the SOLIDWORKS package and the support we receive is amazing.

Intelligent Solutions Produce Huge Bottom-Line Savings

A Trident customer in the waste recycling industry was experiencing significant downtime due to repeated system failures. After analyzing the customer’s existing setup, the Trident team began with maintaining the current hydraulic system that was plagued by issues such as hydraulic oil overheating and component failures.

Forester designed a new upgraded intelligent servo-driven hydraulic system that delivered impressive results, including savings of hundreds of thousands of dollars per year in electricity costs. What started as a fix for one facility is now being rolled out to other sites.

Seeing is Believing

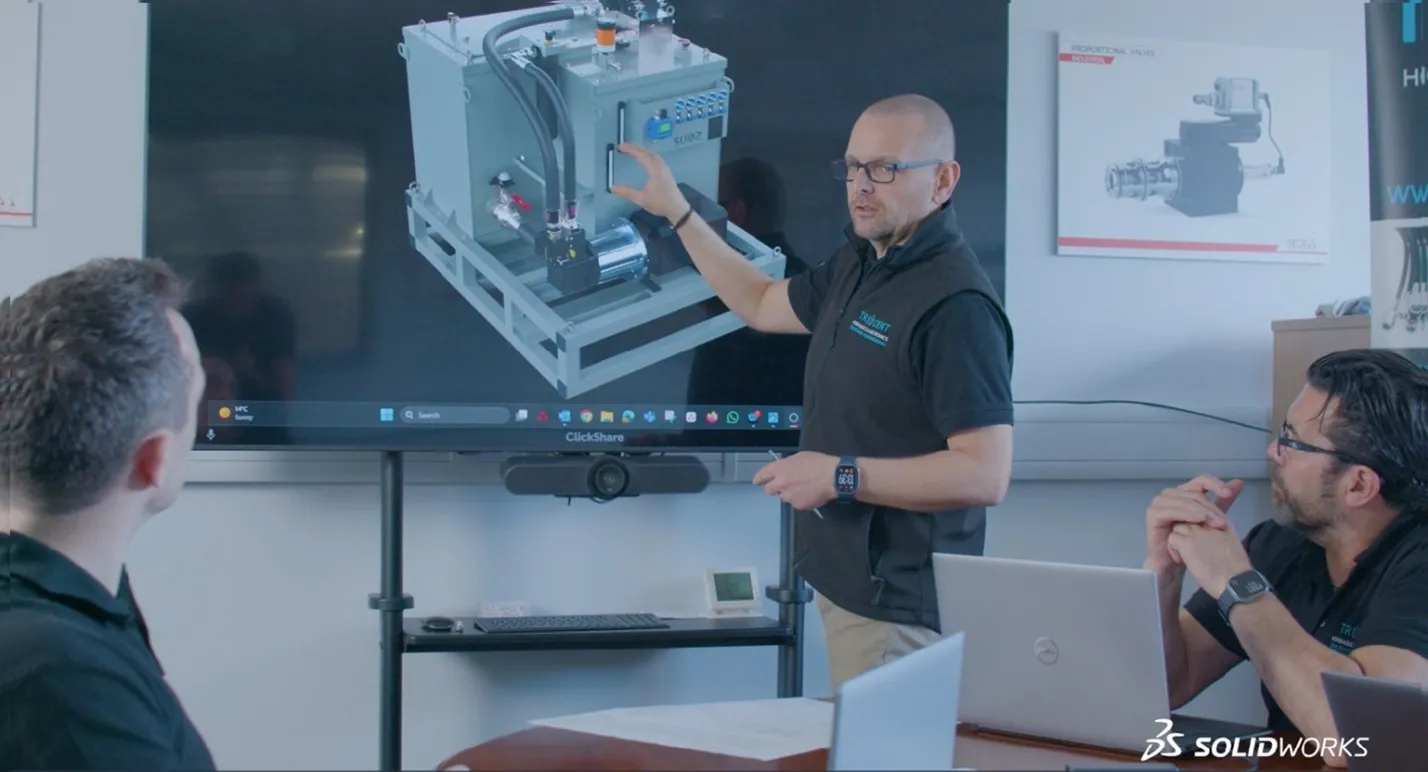

Beyond engineering, Trident leverages SOLIDWORKS Visualize to communicate ideas and demonstrate system functionality. “It’s great to not only explain how a system works but also to show customers a real-life model,” Owen observes. This capability builds trust instantly and helps Trident promote its solutions in the marketplace.

Trident enjoys a clear competitive edge with faster time to market, yet Owen concludes with another key benefit of SOLIDWORKS: “There are comparable tools out there, but the SOLIDWORKS package and the support we receive is amazing.”

From Concept to Production

Trident’s innovation is rooted in customer-led R&D: They treat clients not just as recipients of technology, but as collaborators in its creation. This continuous feedback loop informs everything from component design to full-system development, which ensures each solution is grounded in real-world insight and engineered for long-term performance.

Today, as the Trident team continues to expand its capabilities, SOLIDWORKS Premium with Cloud Services and SOLIDWORKS Visualize Professional remain central to their strategy. From idea to implementation, SOLIDWORKS is the core system enabling them to produce higher quality products faster and more efficiently.

Products:

- SOLIDWORKS Standard

- SOLIDWORKS Visualize