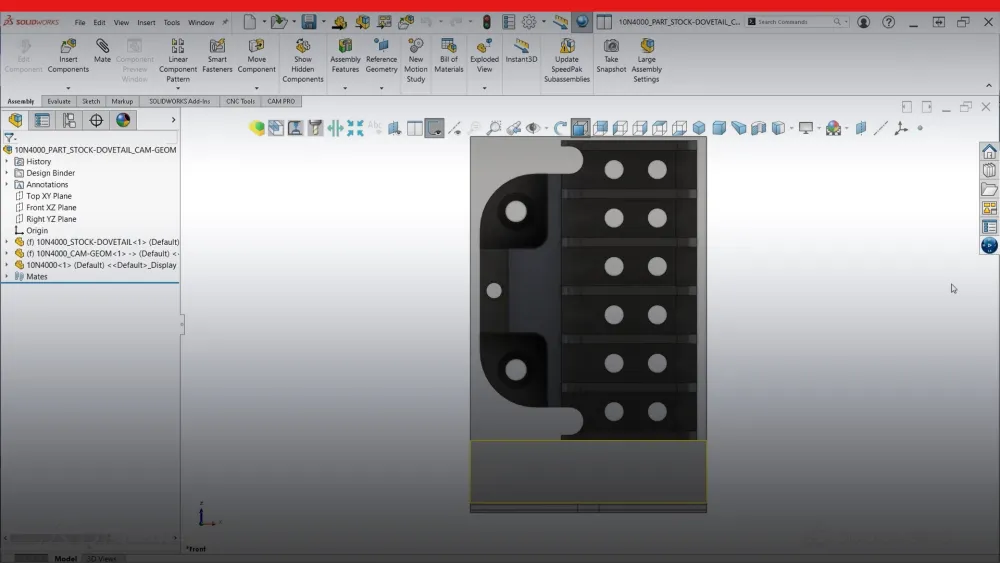

Program Robots Right the First Time with 3D Robot Programmer

The use of robotics in manufacturing has grown, however, because robot programming is not part of the design phase, manufacturing personnel must often scramble to implement fixes and workarounds on the shop floor, which leads to potential conflicts. With Robot Programmer, users can deliver high-quality, collision-free programs in the native robot language with minimal intervention on the shop floor. In the virtual world, programmers and designers can work together to create the most productive tooling operations and robot cycle times. Programming can move ahead independently without interrupting the current production schedule, and reducing edits in the floor.