Building Business Around Design

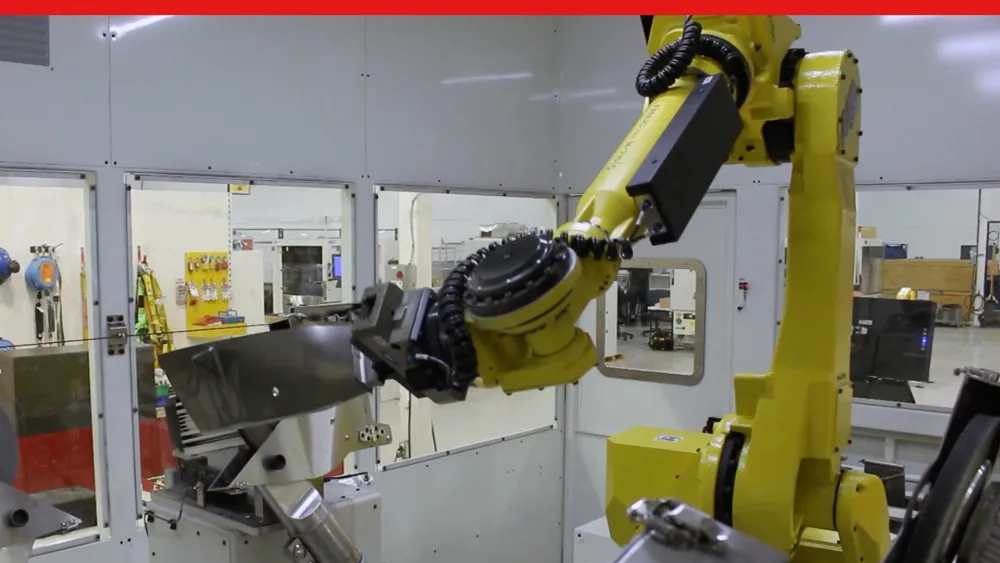

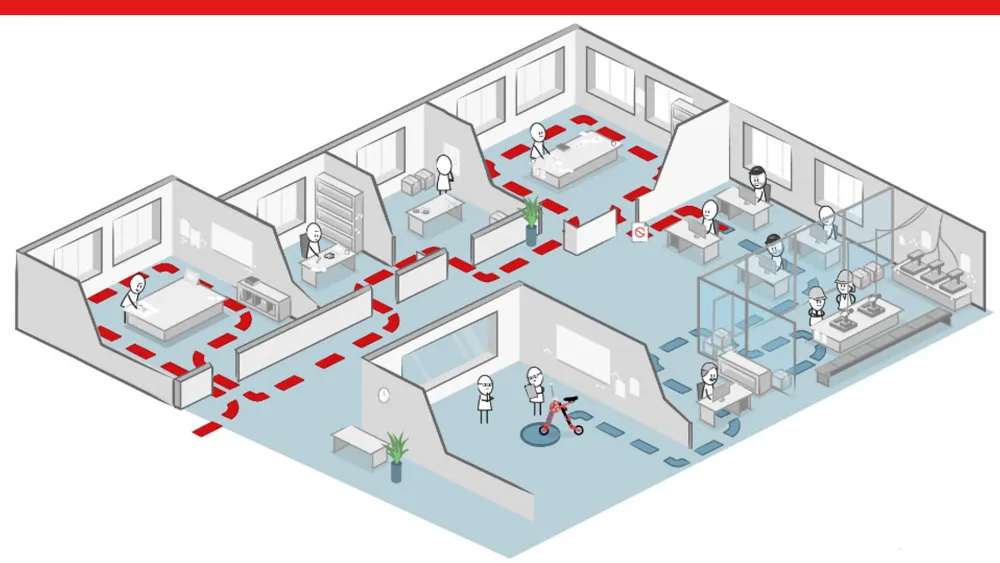

AV&R is a global leader in automation technology, vision and robotics technology with a unique expertise in automated robotic finishing of gas turbine parts, such as the blades used in jet engines. The company uses SOLIDWORKS solutions in all facets of its business and across multiple departments within its organization from design and assembly to prototyping and data management.

Watch the videos below to learn how SOLIDWORKS design-to-manufacturing and PDM solutions and 3D printing help AV&R keep multi-disciplinary teams in synch so they can design and build automated robotic cells capable of optimizing the designs of its aerospace customers for maximum performance and efficiency.