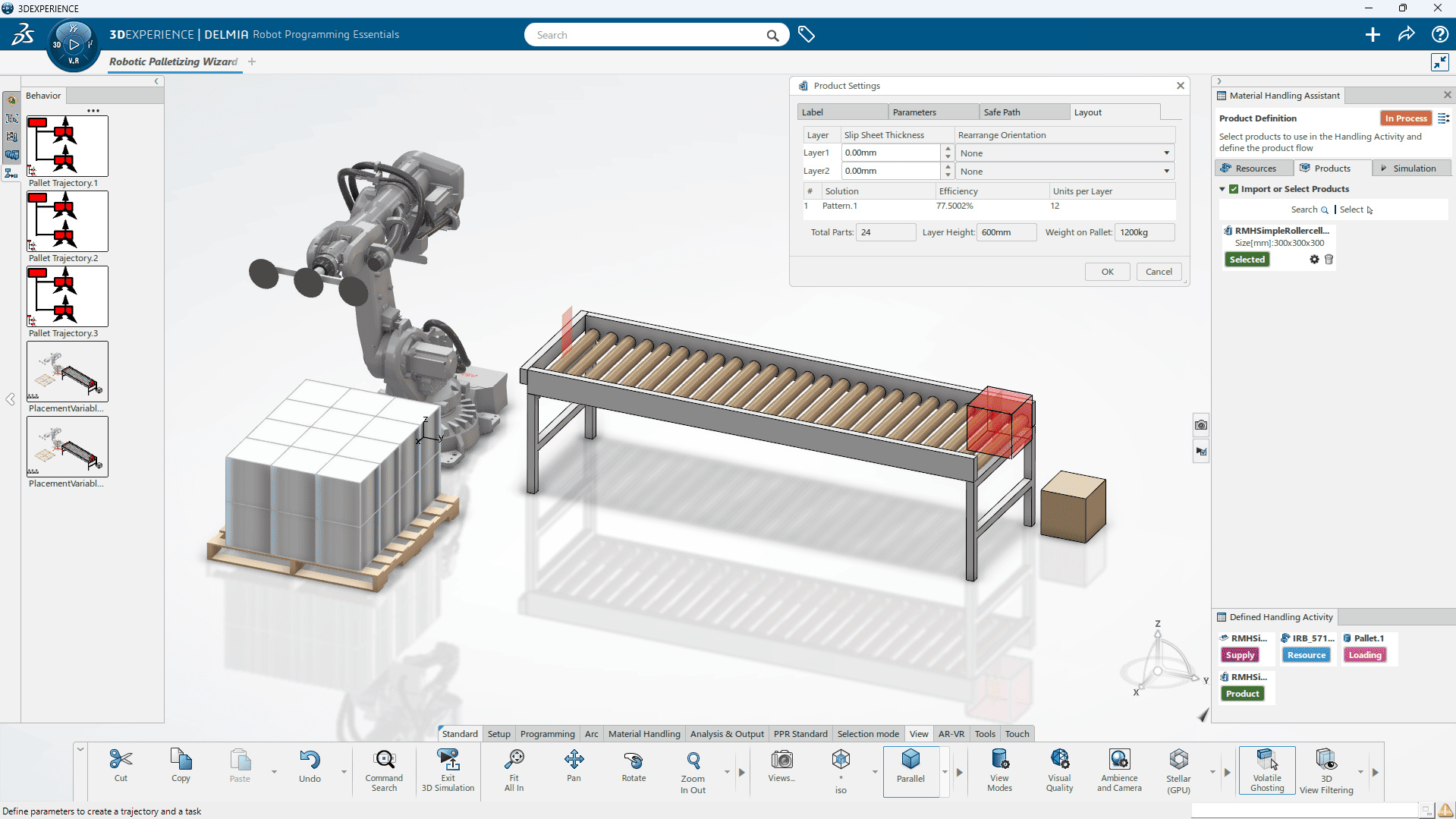

What is Robot Programmer?

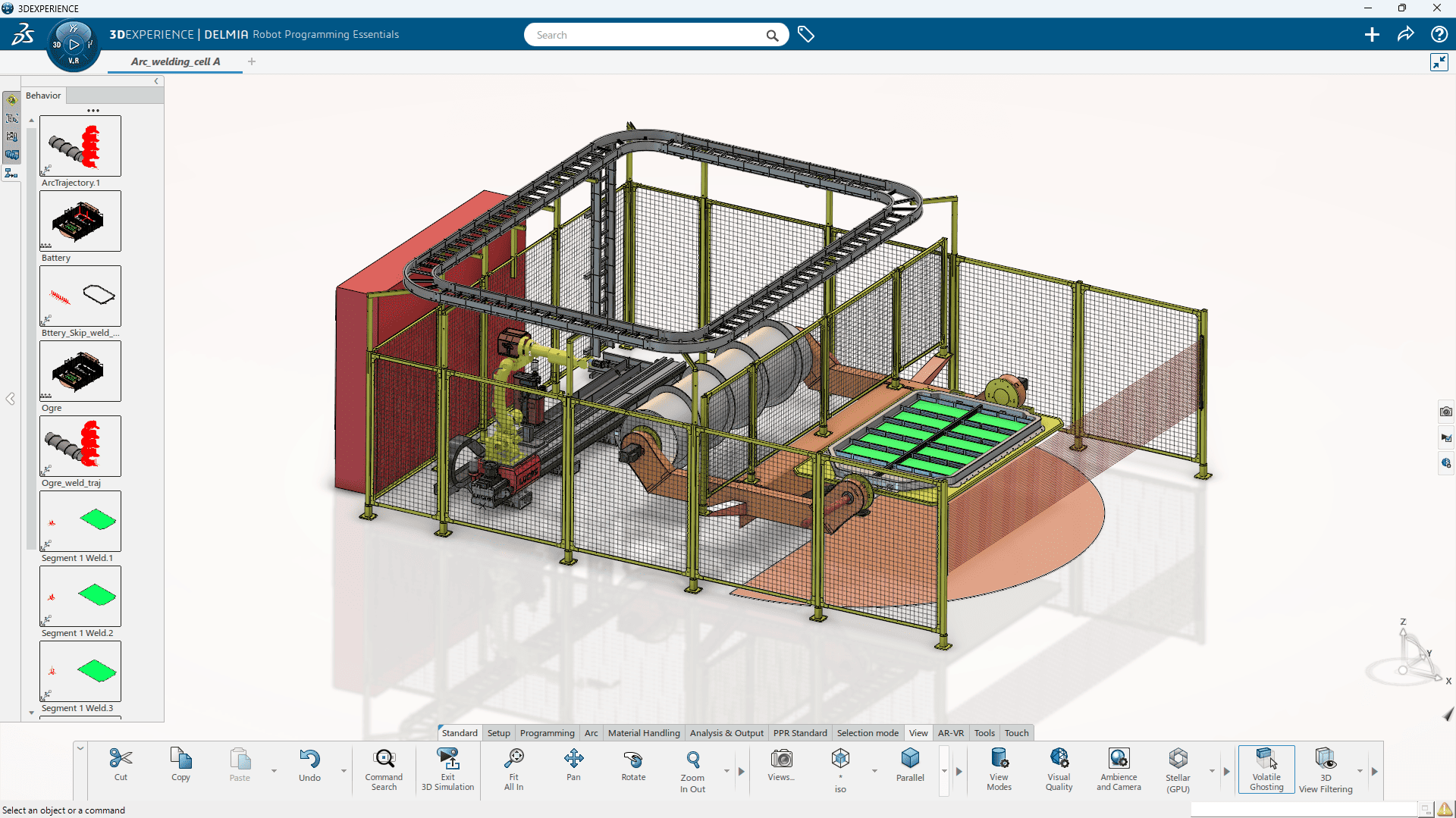

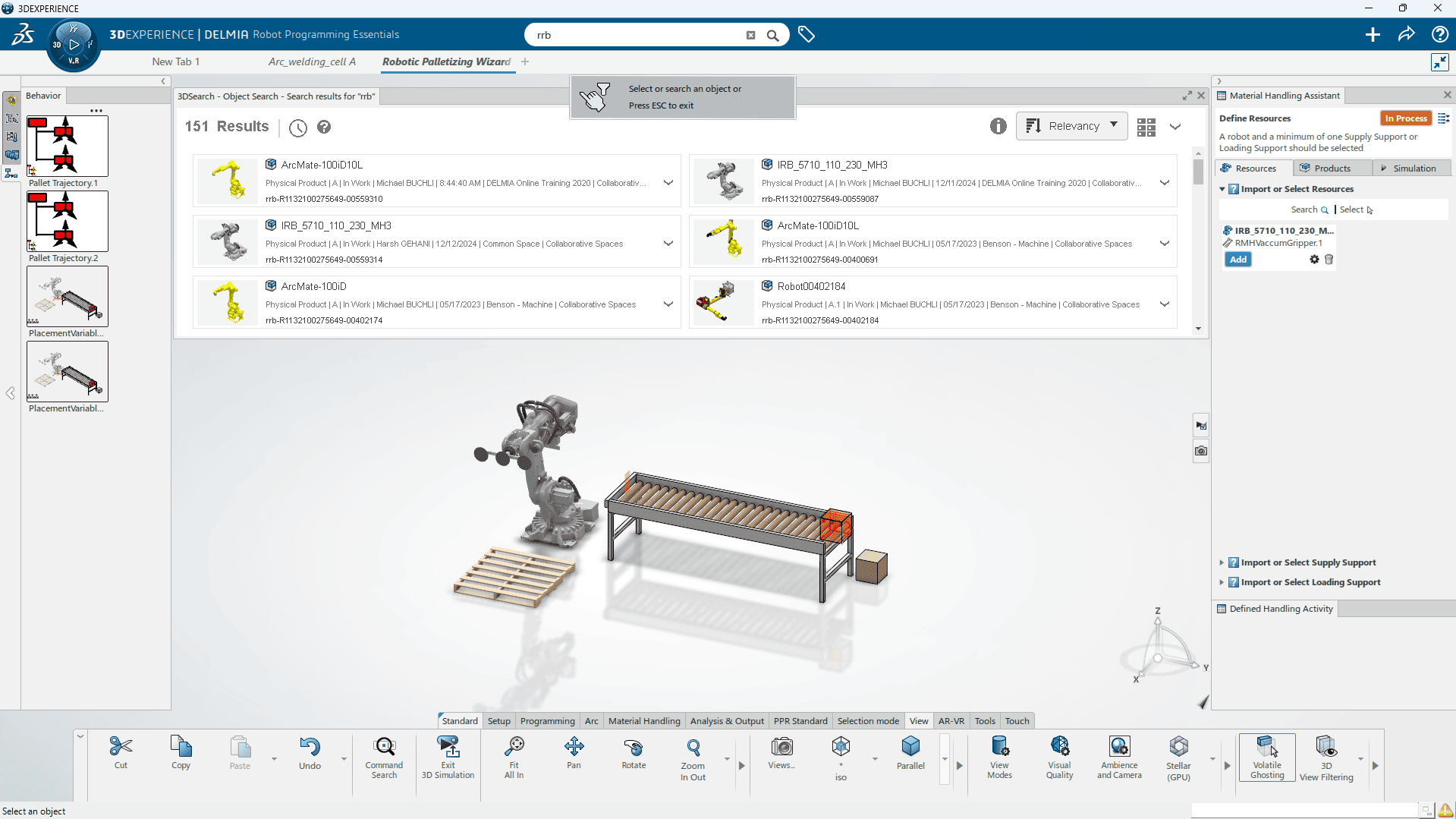

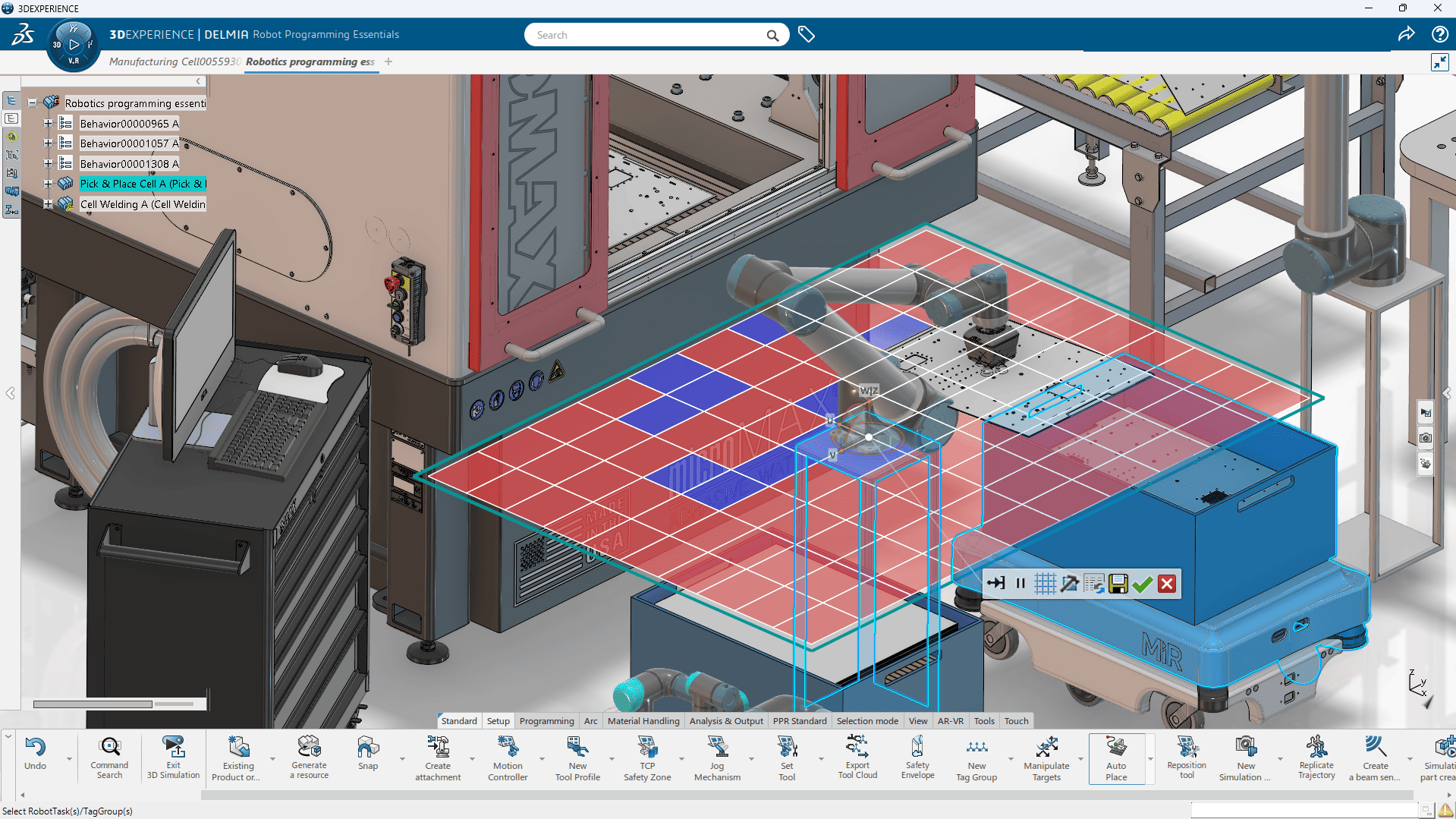

The Robot Programmer role enables users to simulate and validate robot tasks to eliminate errors before implementation. Whether you’re looking to fully automate a system or add a robot (cobot) to work collaboratively with an operator, robots using advanced programming can automate repetitive tasks, delivering benefits that will be seen immediately.

Benefits include:

- Reuse current production robot programs to accelerate changes and adjustments in existing cells

- Offline programming software so users can develop and test robotic programs without halting production

- Seamless SOLIDWORKS integration and connection to the 3DEXPERIENCE platform

- User-friendly UI tailored to advanced robotics programming needs

- Visualize robotic functions in real-time to catch potential issues early and reduce costly errors down the line