Challenge

- Rapidly develop and commercialize ultraviolet disinfection technology for disinfecting common handheld items like tools, phones, and tablets to meet market opportunities resulting from the COVID-19 pandemic.

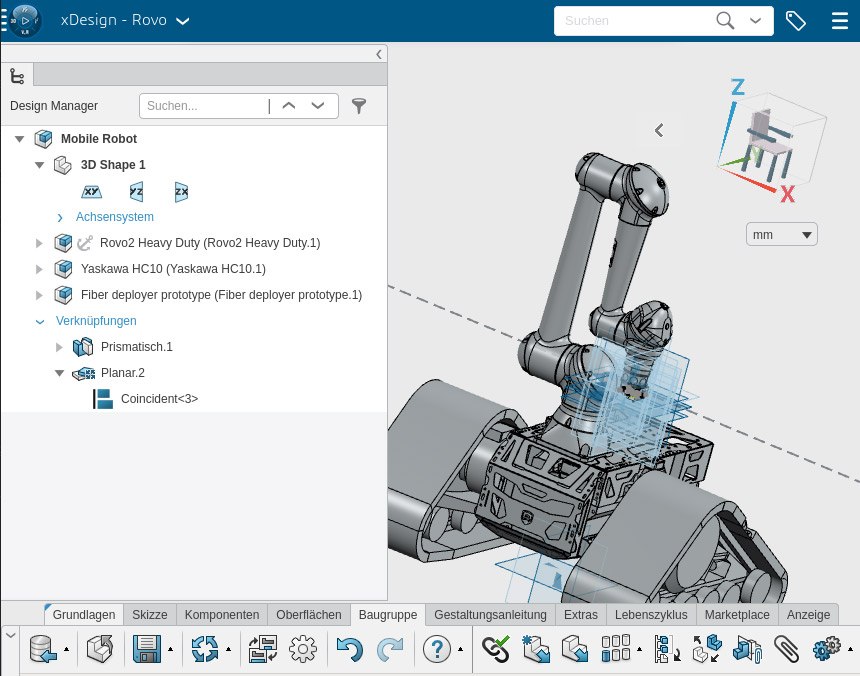

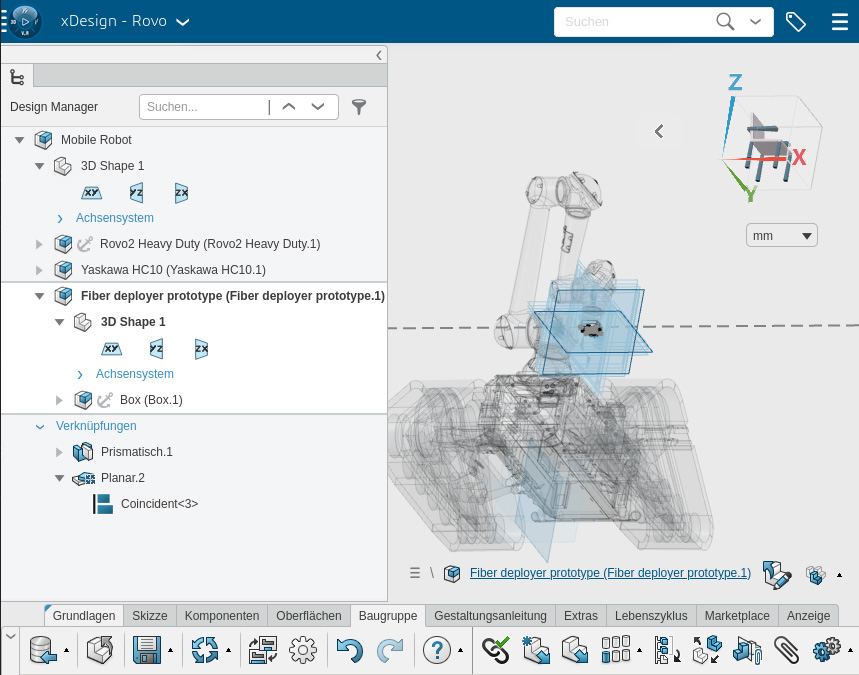

- Develop a robotic rock farming system to build and a maintain rock-wall carbon capture system and complete other farming tasks.

Solution

Adopt SOLIDWORKS 3D Sculptor (featuring the xShape app), SOLIDWORKS® 3D Creator (featuring the xDesign app), and ENOVIA® Collaborative Industry Innovator (featuring the Lifecycle app) industrial design, mechanical design, and product life cycle management solutions on the cloud-based 3DEXPERIENCE® product development platform.

Results

- Conducted R&D on dual robotic rock farming system in cloud

- Continued robot development despite pandemic lockdowns

- Accelerated robotic rock farming system development

- Reduced development costs substantially