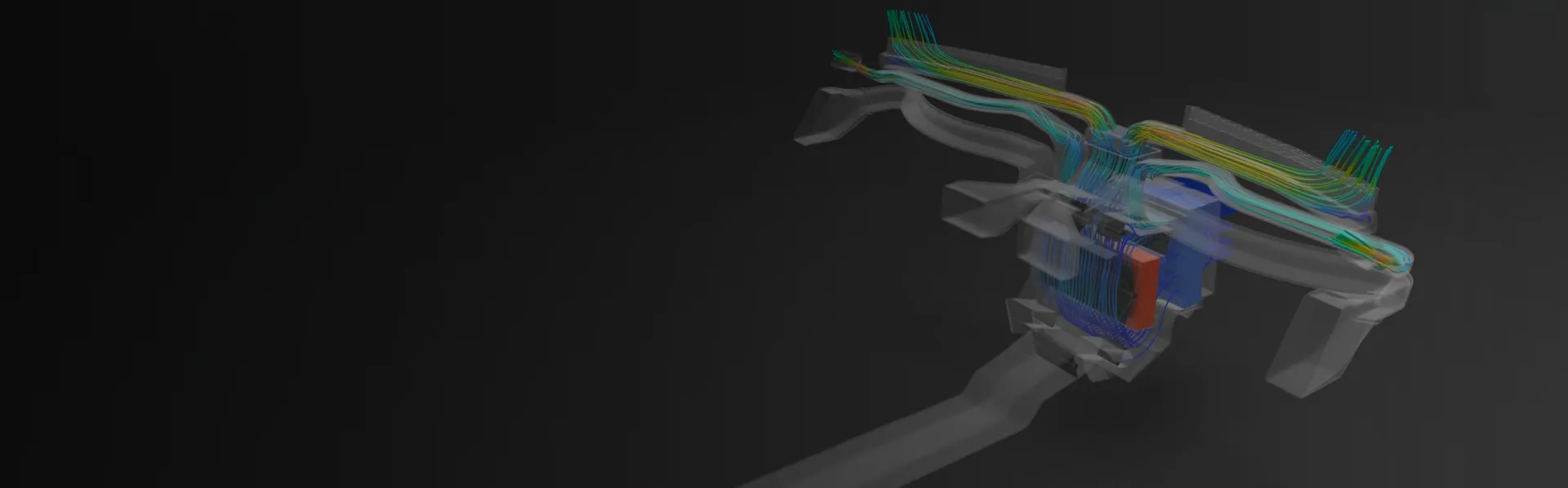

Why CFD?

CFD solutions allow product developers to analyze and optimize designs in a virtual environment by accurately simulating fluid flow and thermal dynamics. These simulations closely mimic real-world conditions, enabling engineers to create safer, more durable, and cost-effective products. What’s more, by reducing the need for physical prototypes, CFD accelerates the design process while minimizing development costs.

Big Market

Microprocessors, microcontrollers, integrated circuits, and other chips combined with various sensors continue to enable a massively growing market for smart products, including phones, appliances, and wearables. The trend for powerful electronics is not just reserved for consumers. Industry has also taken hold of these technologies for manufacturing (IIoT), healthcare (smart implants), and transportation (EVs)—to name merely a few. This trend toward more reliance on electronics drives innovation but comes with trade-offs in thermal management.

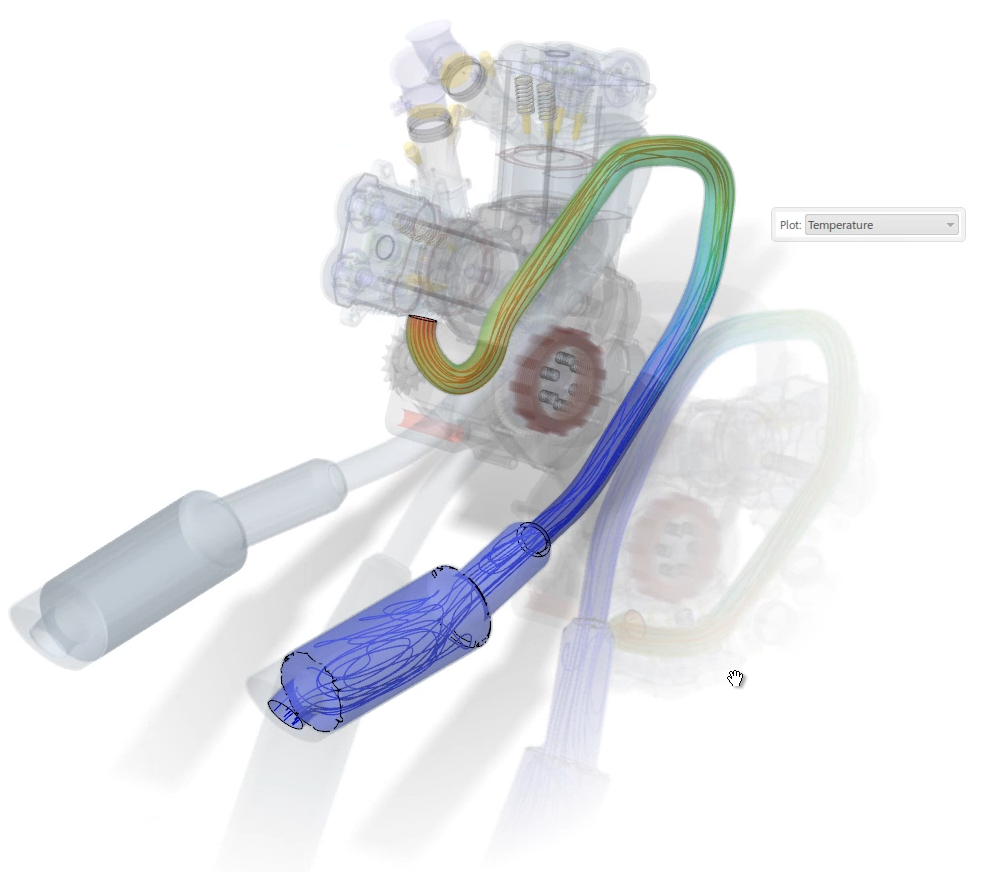

Heat Management

When materials are exposed to high temperatures, their physical properties can change significantly, leading to deformation that undermines structural or signal integrity, functionality, and reliability. Material deformation due to heat is particularly critical because it can cascade into other problems, such as aerodynamic inefficiency, mechanical or electronical failures, or even catastrophic system breakdowns.

CFD is an essential tool for designing durable and reliable consumer and industrial products. It enables engineers to make data-driven decisions by virtually validating design assumptions, leading to higher-quality outcomes. From the earliest stages of development, CFD simulations provide real-world insights that guide design optimization. Accessible to engineers at all levels of expertise, CFD helps enhance performance and reliability while reducing development costs, warranty claims, and time-to-market. By integrating CFD into the design process, manufacturers can consistently meet safety and durability standards with confidence.