Set the Standard for Industrial Equipment Design

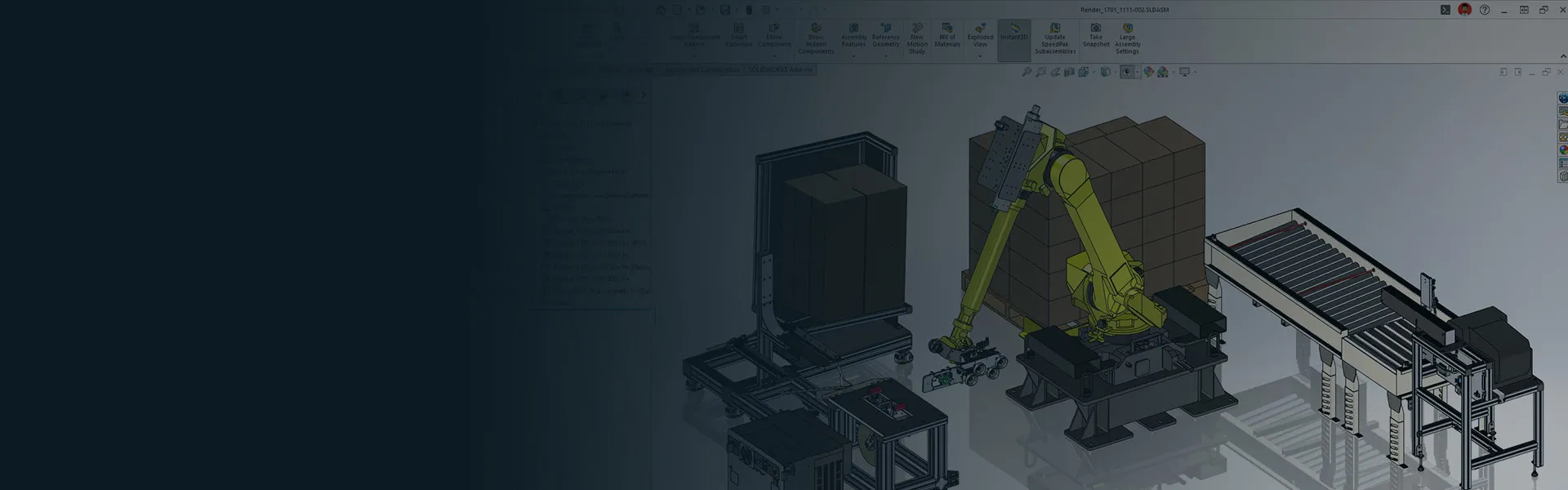

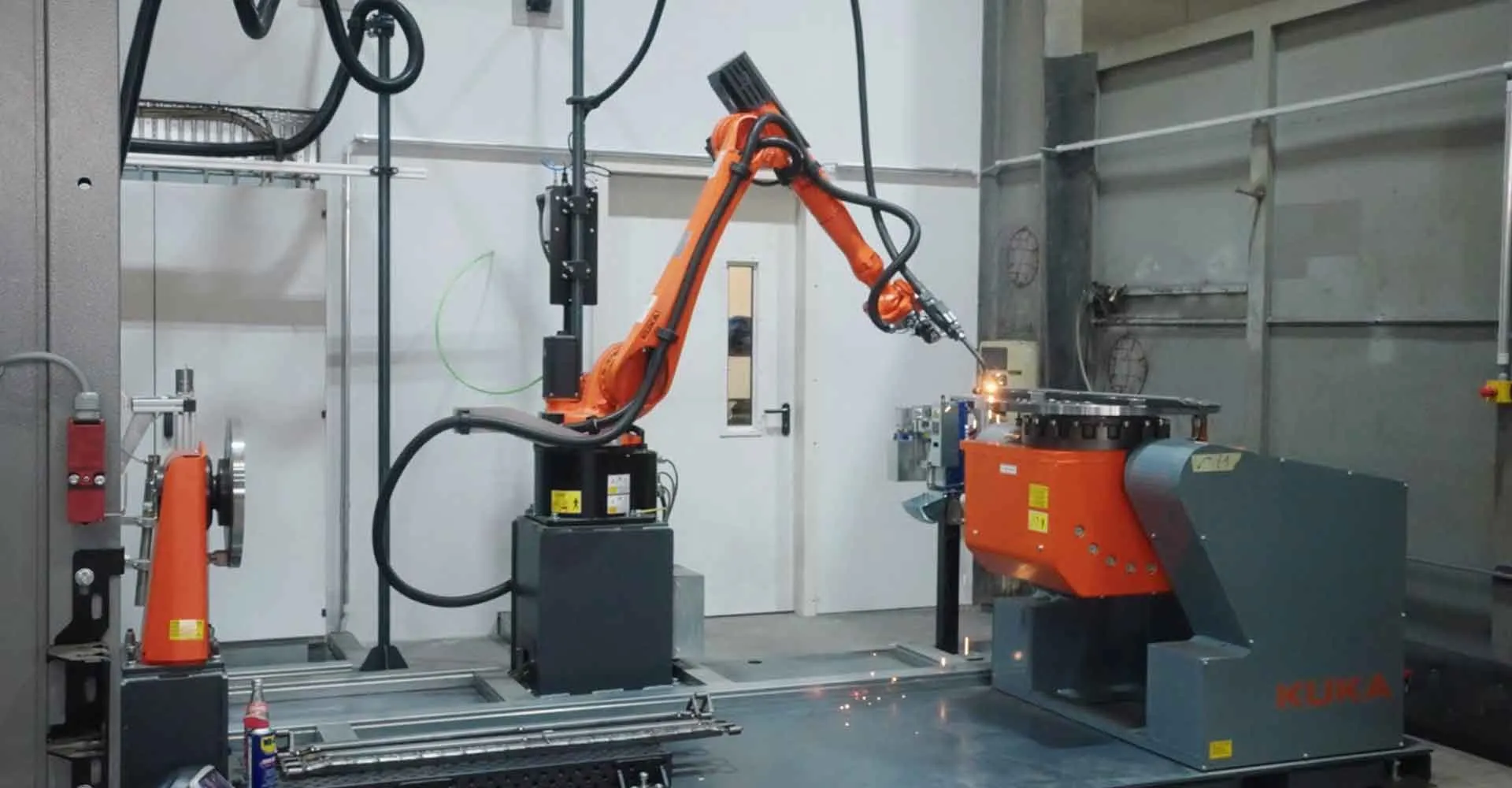

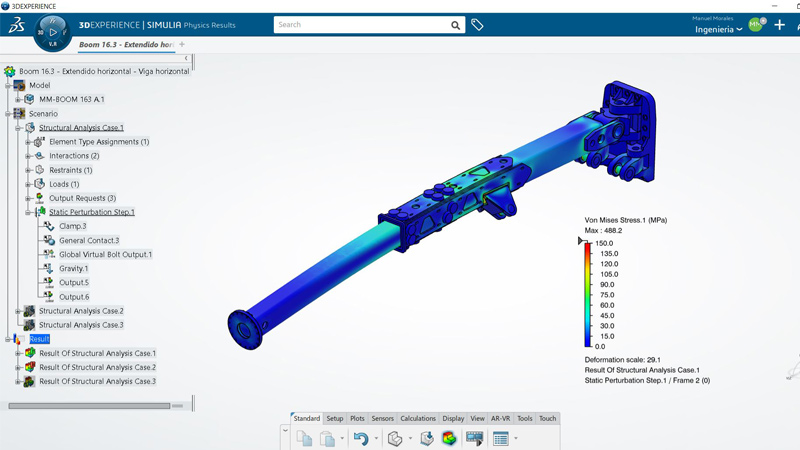

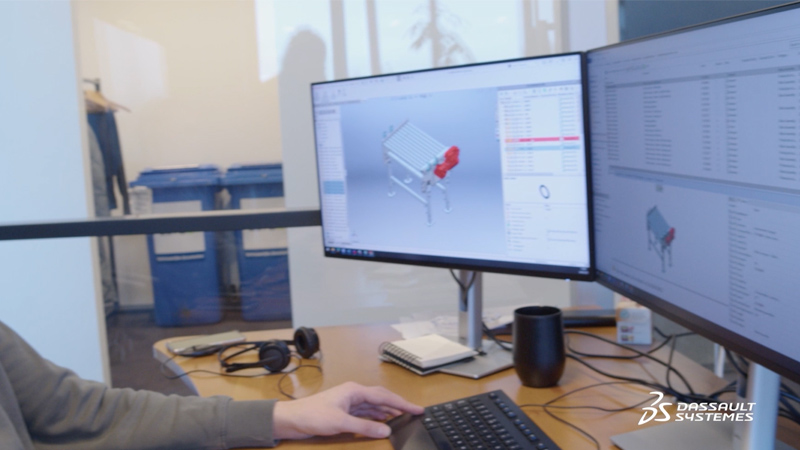

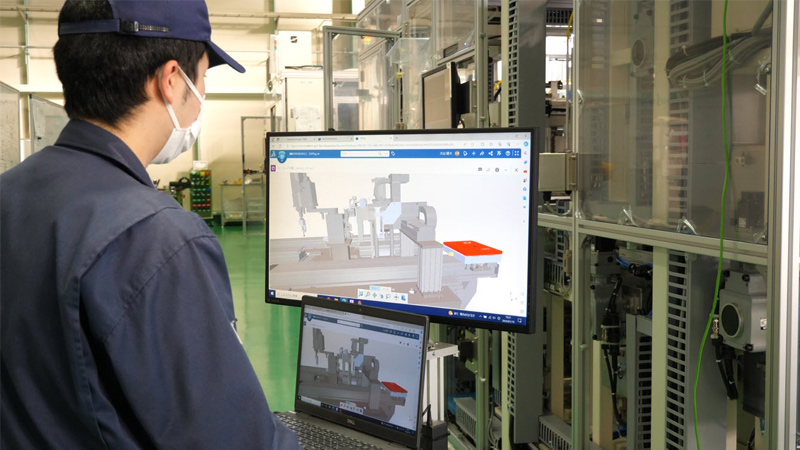

The industrial equipment industry is under constant pressure to deliver innovative products that are durable, efficient, and cost-effective. SOLIDWORKS® offers a suite of purpose-built tools that help manufacturers and engineers tackle these challenges head-on. Designed to meet the specific demands of industrial equipment manufacturers, SOLIDWORKS improves product design, streamlines workflows, and integrates cutting-edge technologies.

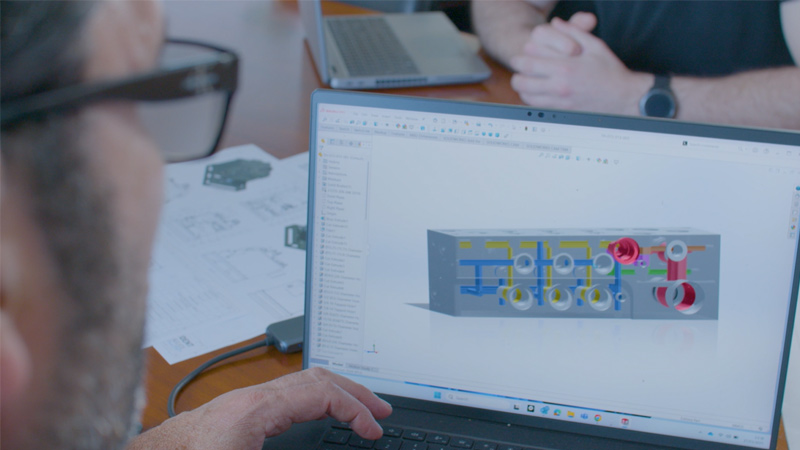

From parametric 3D CAD design to advanced simulation and manufacturing automation, SOLIDWORKS provides a complete solution for developing better machines and staying competitive in the market.