Simulation Software: An Essential Tool for Hardware Startups

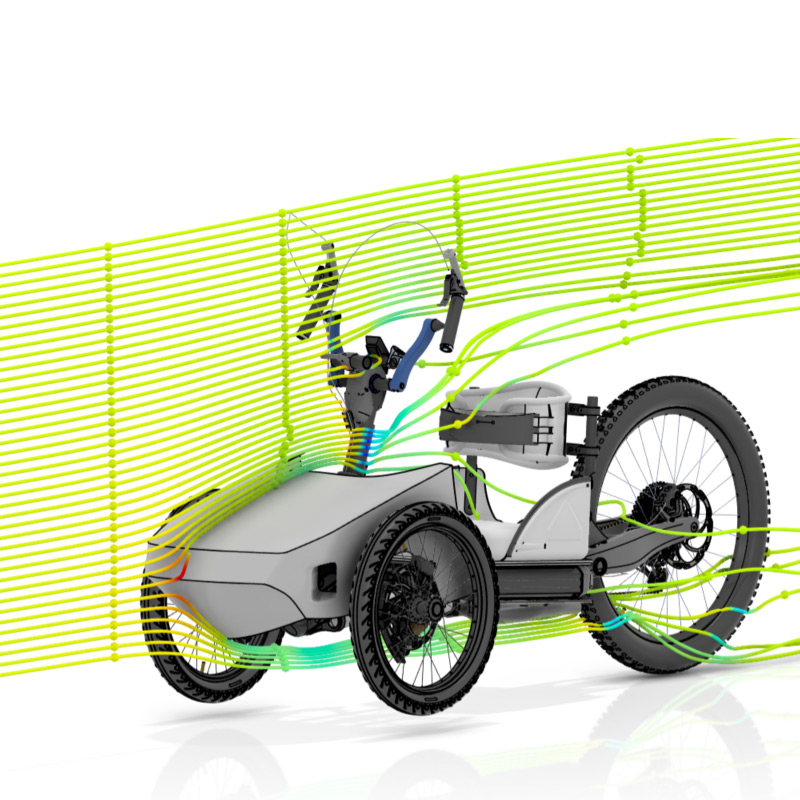

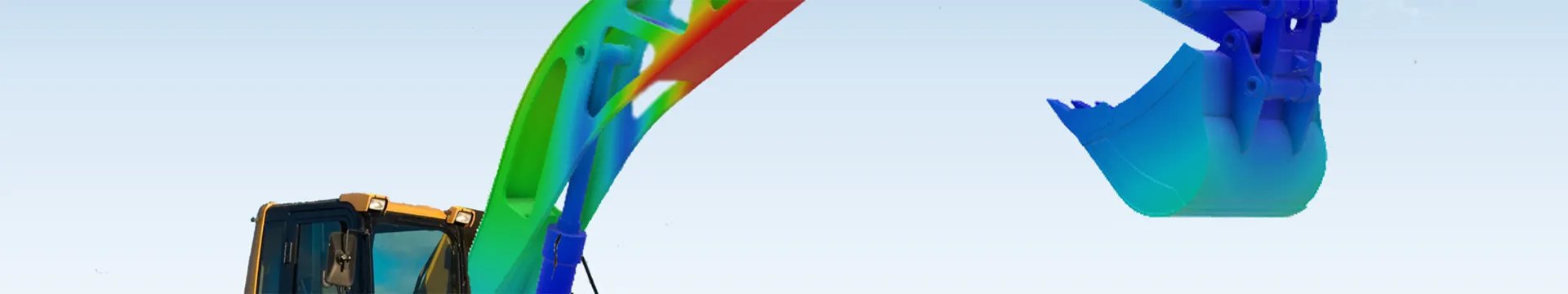

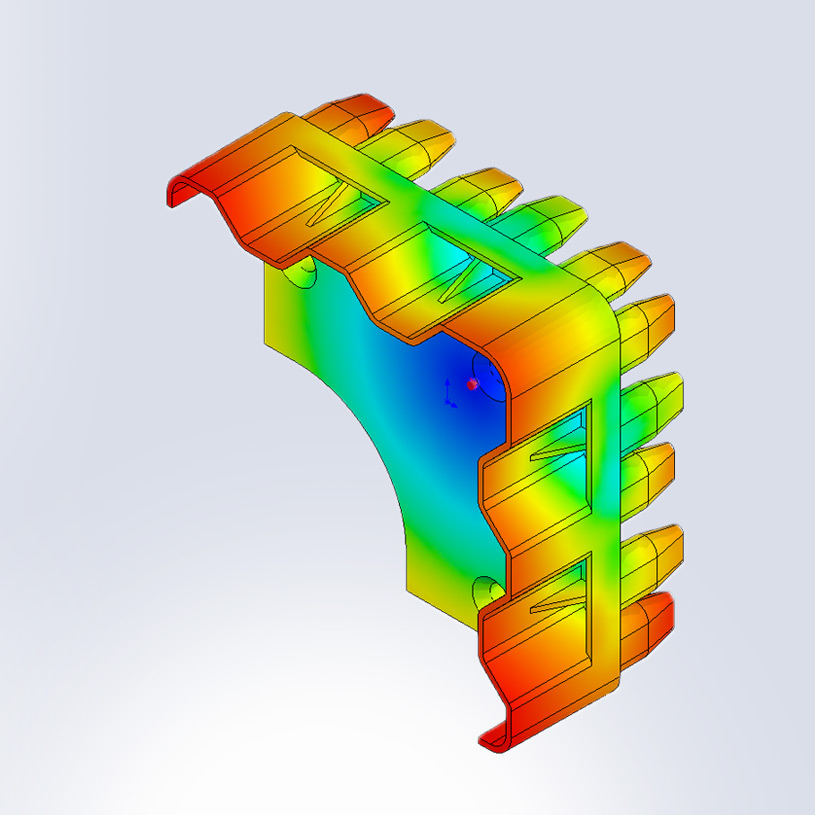

Startup founders often have to manage tight budgets, small teams, and the pressure to get their products to market faster. That’s why, as a startup, making the right choice of product development software is critical. In addition to industry-standard 3D CAD, startups need simulation software to test and refine their designs virtually, which saves time and money on product development. Simulation software helps design teams reduce the number of physical prototypes, catch mistakes earlier in the product development cycle, validate product performance, reliability, and safety, and make better-informed engineering decisions.

Faster Time to Market

With simulation, startups can test products in hundreds of different scenarios without building a physical prototype. You can quickly iterate on your design, catching and fixing issues early in the process, speeding up product development. For startups, that speed can be the difference between being first to market or playing catch-up with competitors. It can also reduce costs and accelerate time to revenue.

Diversified Product Offerings

When you get a product to market faster, you can move on to creating new products or improving existing ones based on feedback from your target market. Maybe you want to create a premium version of your product or target a new market segment. With simulation, you can explore different design variations quickly and cheaply and offer a wider range of products or enhanced customizations. Simulation can help startups confidently expand their product line and potentially boost their revenue streams.

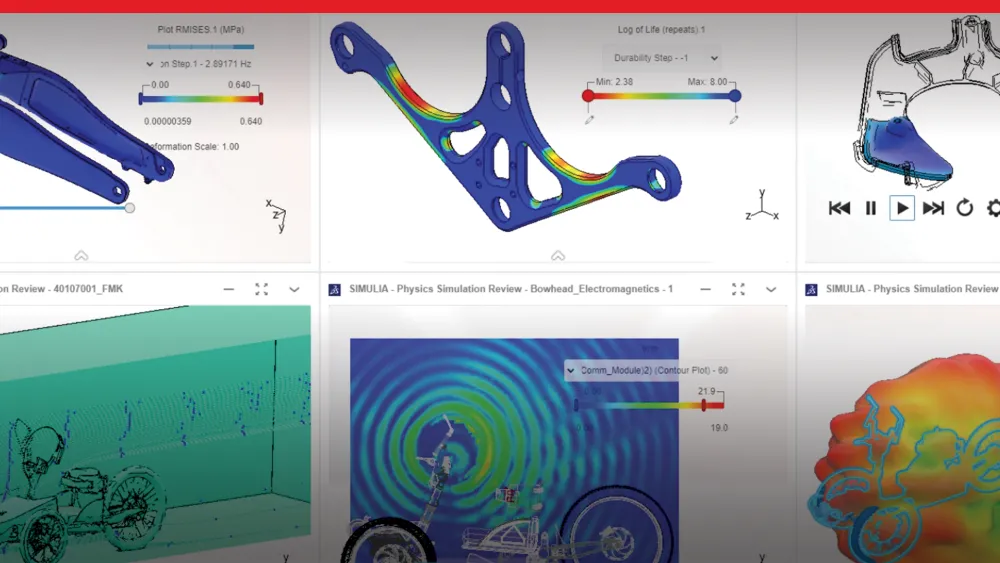

Professional Investor and Stakeholder Presentations

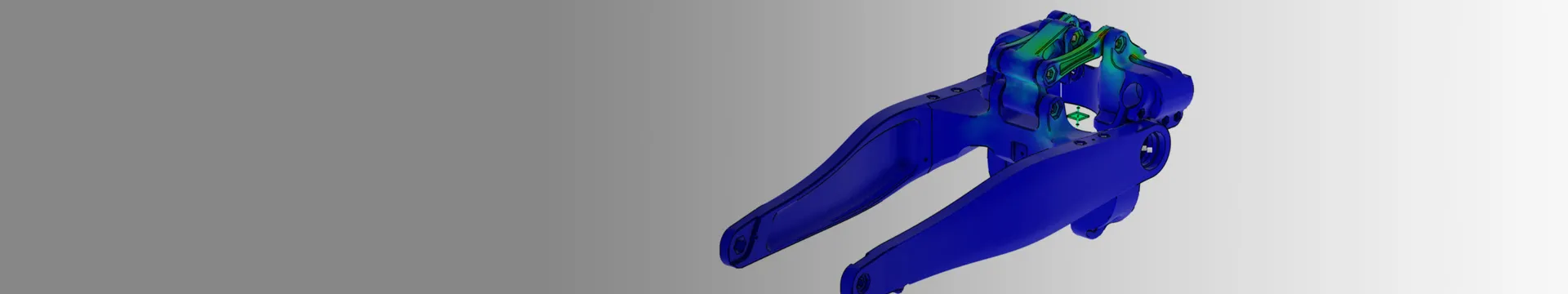

Picture this: You’re in front of potential investors, and instead of showing them a rough sketch or a basic prototype, you pull up a full-color 3D model of your product. You can show them how it works, demonstrate its features, and even show simulation results in the meeting. This level of professionalism shows you’re serious about your product and can impress investors and stakeholders, potentially helping you secure funding or partnerships.