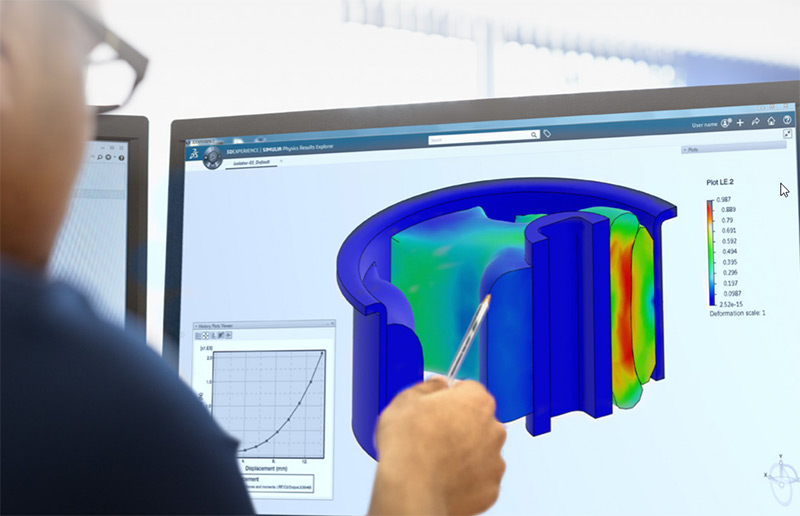

The landscape of product development is continually changing. The integration of simulation tools with cloud-based platforms and technologies such as artificial intelligence is redefining the way engineers and designers approach innovation. By unifying modeling and simulation (MODSIM), manufacturers can keep pace with increasing consumer demands for quality, customization, and sustainability, and set new levels of efficiency and creativity.

Simulation has become a strategic imperative. It empowers companies across all industries to minimize costs, enhance product quality, foster innovation, and champion sustainable practices, all while accelerating time to market.