Key Benefits of Advanced Machining

Let’s explore some of the key benefits of implementing advanced machining processes and technology across modern manufacturing environments.

Precision and Complexity

As products become more complex and materials become more specialized, manufacturers need advanced tools to handle these challenges. Advanced machines and tools can produce parts with higher tolerances and more complex geometries, precisely shaping every workpiece in ways traditional methods cannot easily achieve.

Increased Productivity

Modern technologies, like CNC machines, robots, and automated workflows, streamline the traditional manufacturing process. Automation also reduces human error and dependence on manual labor, leading to faster production and less downtime. This efficiency helps manufacturers produce more parts in less time, improving throughput and lowering costs

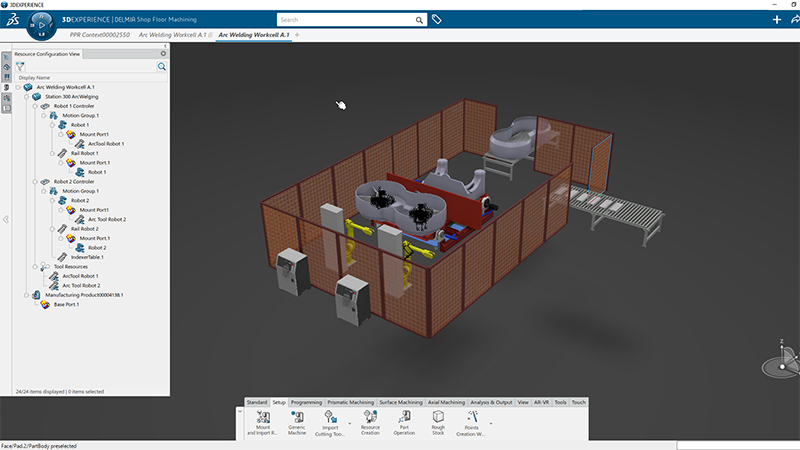

Automation and Smart Technology

Use of automated systems, sensors, and real-time data analysis to optimize processes, increase production speed and reduce human error.

Multi-process Integration

Combining machining processes (like turning, milling, grinding, welding and drilling) into one setup, often through CNC machines, to improve efficiency and reduce the need for multiple tools or operations.

Enhanced Flexibility and Customization

Advanced machining tools enable users to easily switch between different production runs or quickly adapt to customer orders. CNC and 3D printers allow for more flexible, on-demand production of customized parts, making it easier to meet customer needs or create low-volume, highly specialized components.