A New Era for Robotics in Small Businesses

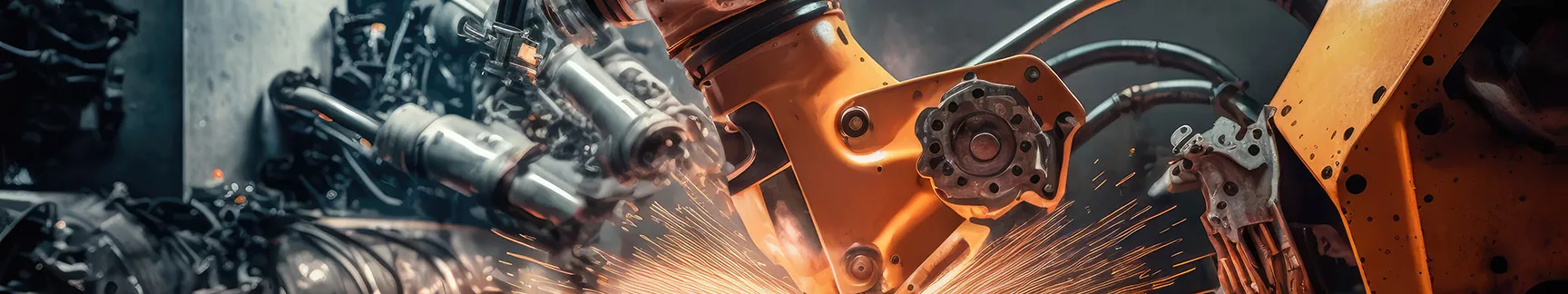

Robotics offers small and medium-sized businesses (SMBs) a powerful tool to boost efficiency, productivity, flexibility and growth. By automating repetitive or labor-intensive tasks, such as welding, painting, and assembly line functions, various types of robots help reduce costs and minimize errors, allowing businesses to allocate resources more strategically. Robotics also enables SMBs to compete more effectively, not just by increasing throughput but by delivering consistent, high-quality results that elevate customer satisfaction. Adopting and using robotics isn’t just about staying competitive today; it positions SMBs to meet the challenges of tomorrow with agility and innovation.

Why Cobots Are Gaining Momentum with SMBs?

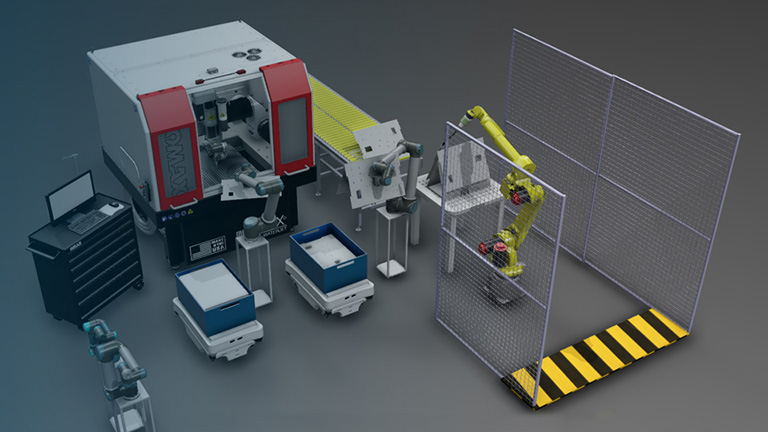

As robotics adoption expands, many robotics companies are focusing on cobots, or collaborative robots equipped with artificial intelligence (AI), which are specifically designed to work safely alongside human workers. Unlike traditional industrial robots, cobots require less space, minimal guarding, and can be more easily integrated into existing workflows—making them ideal for small and mid-sized manufacturers.