Challenge

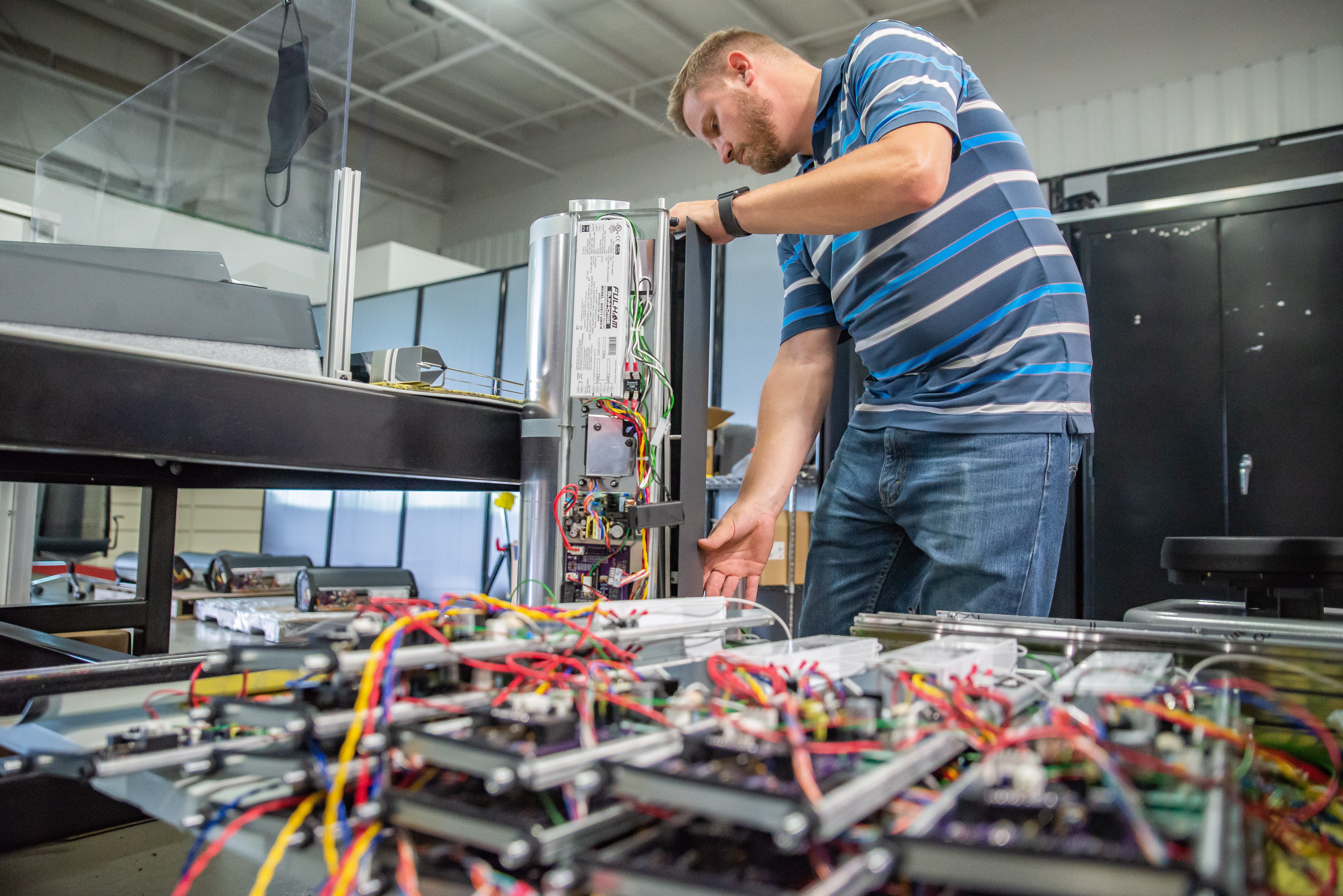

Rapidly develop and commercialize ultraviolet disinfection technology for disinfecting common handheld items like tools, phones, and tablets to meet market opportunities resulting from the COVID-19 pandemic.

Solution

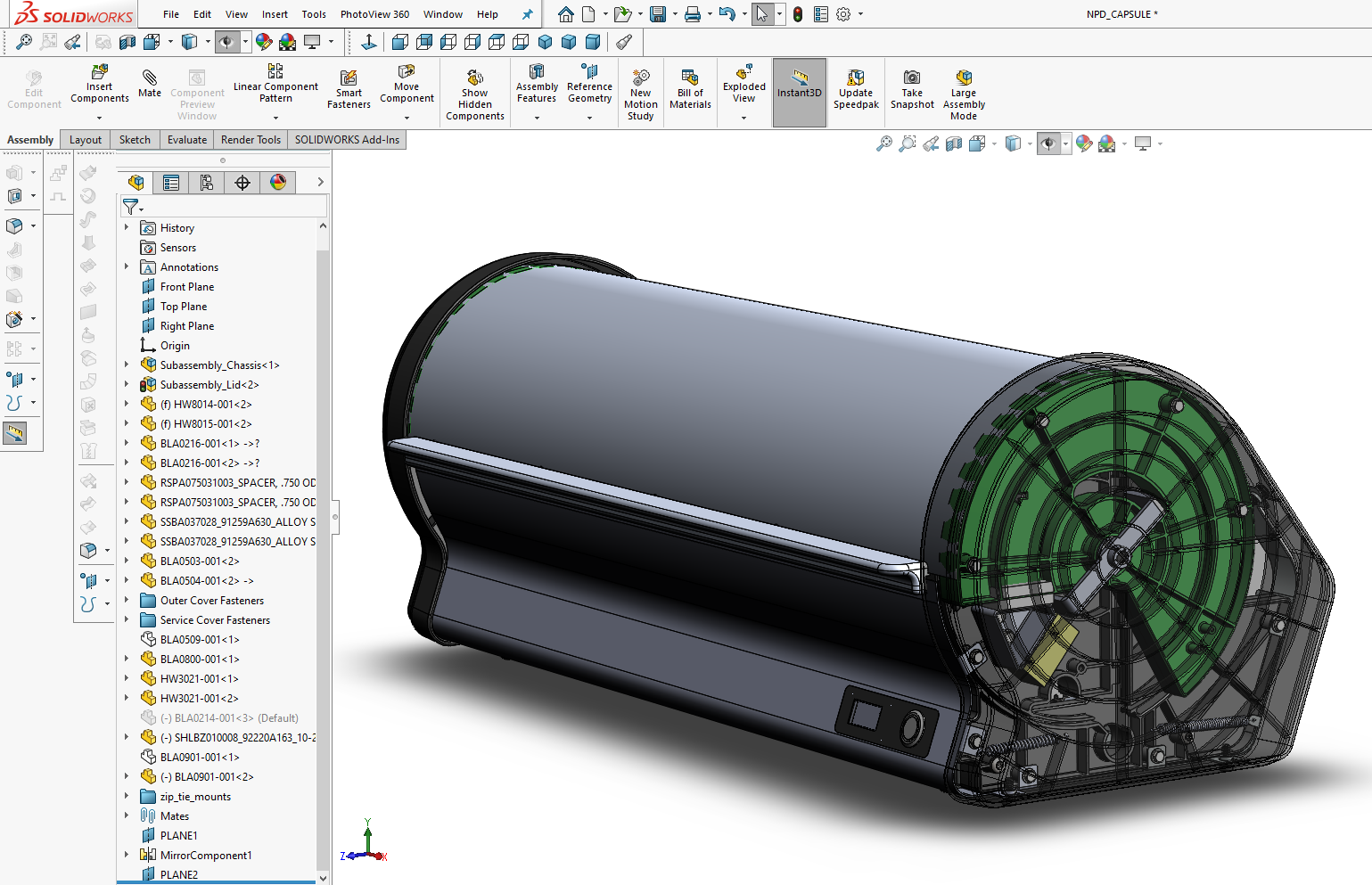

Utilize integrated SOLIDWORKS product development solutions to quickly bring ultraviolet disinfection technology to market.

Results

- Cut development cycle in half

- Quickly validated door-closing design via simulation

- Launched new company during pandemic

- Commercialized ultraviolet disinfection technology into broader markets Challenge: