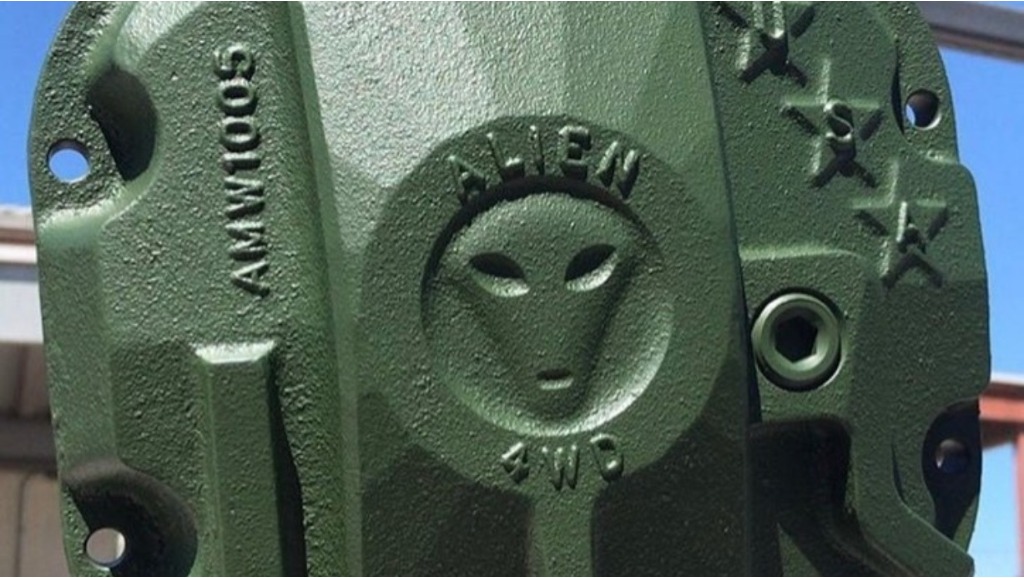

Tim Fulton’s passion for off-roading started at age 16. It was no surprise then that in 2004, Fulton founded Alien Machine Worx, which develops rugged, functional differential covers for off-road vehicles, including breather manifolds, hubcaps, billet knobs for shifters, sunshields, and more.

Fulton did contract work for a variety of manufacturers for several years. “SOLIDWORKS® design software … is easy to use and can handle just about any CAD or data formats that come through the door. For customers who don’t have data but have sketched their ideas out on paper, it’s easy to use SOLIDWORKS to model the part and produce the data from which it can be machined,” says Fulton.

“I love SOLIDWORKS [CAD], so I knew that SOLIDWORKS CAM would make a dramatic difference when it comes to tool-path programming. Having access to integrated SOLIDWORKS CAM capabilities has really made a difference in helping us launch our product line, fulfill orders quickly and cost-effectively, and improve our competitive position,” Fulton continues.