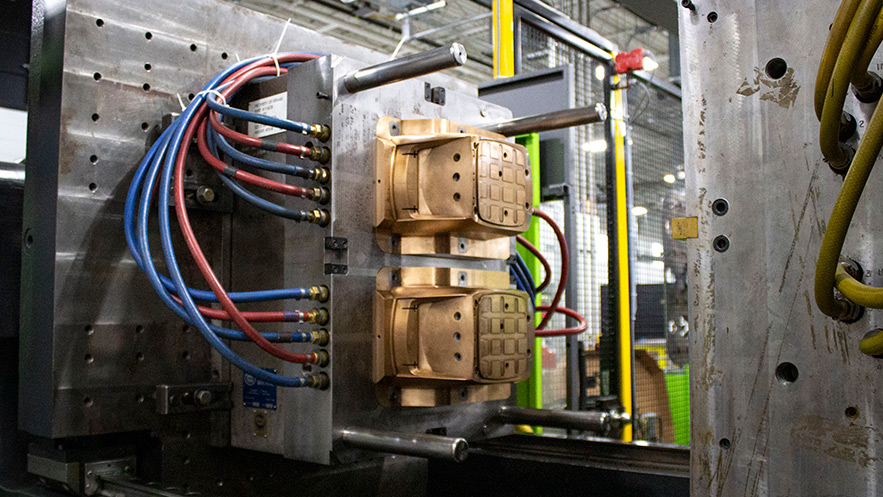

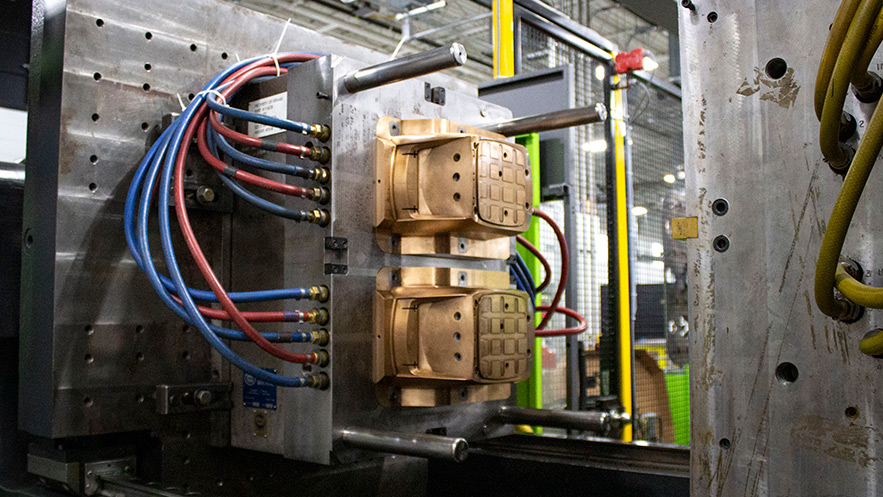

Founded in 1950, Thogus Products is a family-owned, custom plastic injection mold and contract manufacturer headquartered in Avon Lake, Ohio. With a customer-first focus, Thogus is committed to building lasting relationships with customers and suppliers.

To better leverage its operational data, Thogus implemented the DELMIAWorks enterprise resource planning (ERP) system from Dassault Systèmes in 2021. The company selected DELMIAWorks ERP because it is specifically designed for injection molding, machining, production, and manufacturing services-based enterprises, providing accurate information on inventories and production operations as well as business and financial information.

“We no longer have any wiggle room and must be as efficient as possible,” points out Director of Finance Alois Chasko. “Many of our employees had their own workaround processes that added unnecessary data to our ERP database, which had become bloated and was creating unnecessary storage expenses at our data center.”

Reducing Costs

The previous data system was also plagued by data corruption and errors. “Management needs access to accurate, reliable information to make the right business, staffing, and scheduling decisions,” stresses IT Manager Mark Szuminski. “The information in our previous system was not as reliable as we needed it to be, and that was beginning to negatively affect production, which is why we decided to implement DELMIAWorks.”

Since implementing DELMIAWorks ERP, Thogus has reduced the size of its ERP database by 90 percent, cut data storage costs by 50 percent, and eliminated monthly data storage overage fees.