Challenge

Develop an alternative to continual pedaling assistance, which can be frustrating to electric bike riders who do not need it all the time, especially on flat roads and downhills.

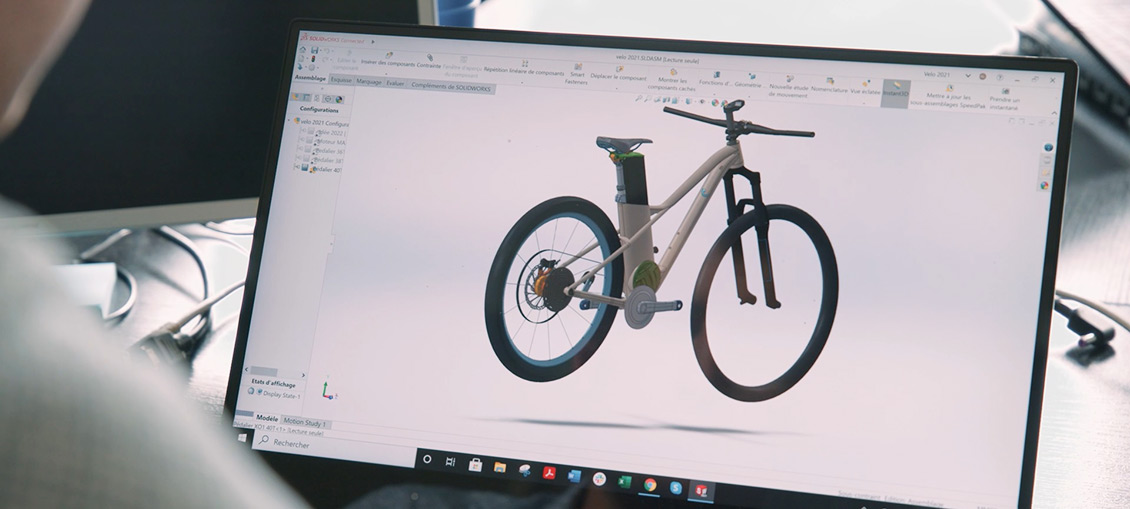

Solution

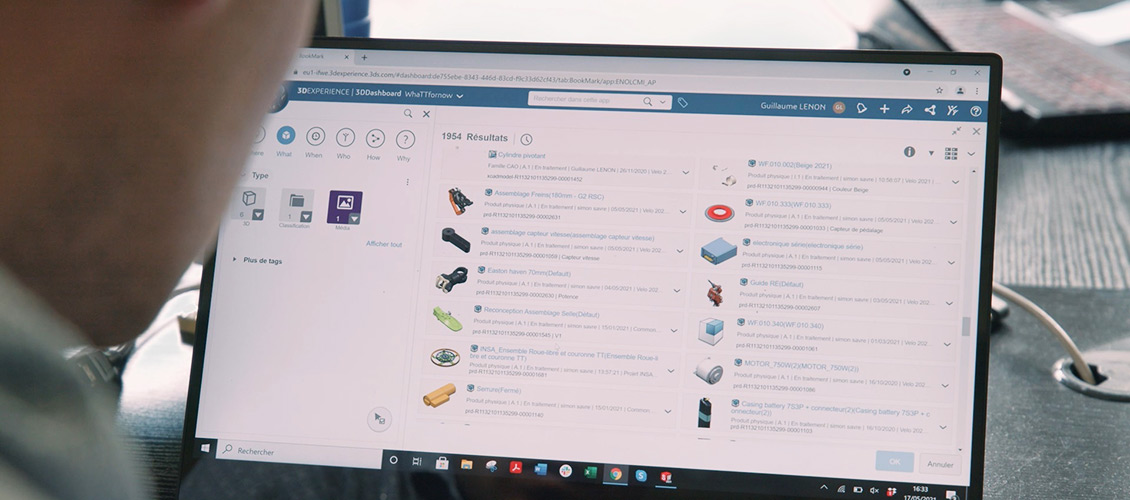

Implemented 3DEXPERIENCE® Works solutions to secure its data in the cloud, better collaborate within its development team, share data, and avoid human error when sending files, especially regarding multiple versions of components.

Results

- Achieved data security on the cloud

- Improved collaboration and data sharing in real-time

- Easy access to data for remote workers

- Better structuring of projects