ZETR avoids unnecessary iterations and streamlines development processes because SOLIDWORKS, in conjunction with 3DEXPERIENCE Works solutions enables a defined, formalized workflow. “When we were using Fusion 360, it was every designer for him or herself, with everyone having their own process,” recalls Romano. “By standardizing workflows and tapping the power of SOLIDWORKS design configurations, we’ve realized 30 to 40 percent time savings on our development timelines and tripled our product line relatively quickly because everyone follows the same process and knows what the next step will be.” In addition to working more efficiently and growing the product line, ZETR has reduced internal design iterations and back-and-forth communications with suppliers and manufacturers.

Setting the Stage for Growth

ZETR has grown at a rate of 50 percent quarter over quarter since implementing SOLIDWORKS and 3DEXPERIENCE Works solutions.

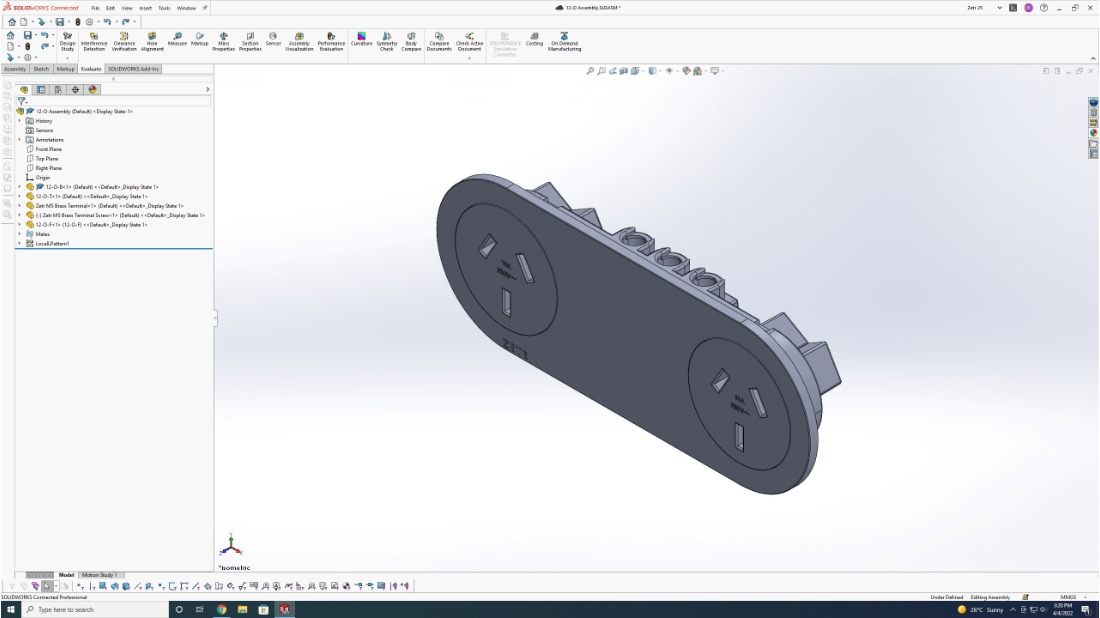

“Now that we have our product development team working efficiently and effectively with SOLIDWORKS and 3DEXPERIENCE Works solutions, we’ve launched an R&D effort to take advantage of the international opportunity presented by a universal standard that requires new and replacement fixtures. We have equipped our product development team with the tools to ramp up development and production as we grow into an international organization,” Romano says.