52 Sounds Engineers Good Vibrations

Music technology provider leverages SOLIDWORKS 3D CAD to create a modular guitar pedal board system to help pro guitarists easily manage, expand, and transport their gear.

Challenge

Combine passions for music and engineering by quickly developing products — beginning with an innovative, modular guitar foot pedal system — that improve the lives of everyday professional musicians.

Solution

Implement 3DEXPERIENCE Works product development solutions as part of the SOLIDWORKS for Startups program.

Results

- Developed patent-pending, modular guitar foot pedal system

- Validated modular guitar foot pedal platform via simulation

- Lowered production costs via 3D printing

- Boosted simulation performance by using cores in the cloud

New Mexico-based 52 Sounds founder Akash Dighe began his mechanical engineer career working for companies involved in engineering advanced high-end systems ranging from spacecraft solar panels to race cars and high-energy laser systems. Dighe designed complex systems during the day and played gigs as the musical artist AKASH at night. It wasn’t until 2023—when he quit his day job and went on a concert tour—that he realized he could integrate his core passions into a single professional pursuit. In January 2024 he established 52 Sounds, where he is musician, producer, product developer, and mechanical engineer.

Precision Matters

Having used SOLIDWORKS® design software from high school through college and employment, AKASH had already been working on some of the concepts before founding his company. He chose SOLIDWORKS to develop musical equipment products because of his familiarity and success with the solution and 52 Sounds. Plus, his company qualified for the SOLIDWORKS for Startups program, which provides free access to SOLIDWORKS and

an expanded portfolio of product development solutions. “I’ve used other CAD systems in the past, but nothing compares to SOLIDWORKS,” AKASH explains. “SOLIDWORKS is a lot more precise. I also value how SOLIDWORKS operates with 3D printers, which will be an important production method [for my products].” Using SOLIDWORKS for 3D CAD and Simulation, AKASH invented a modular approach to foot pedals and pedal boards that makes adding a new pedal literally a snap.

Modular Guitar Foot Pedal System

Guitarists arrange an array of foot pedals on stage to change the sound of their instruments. Often these pedals are mounted on plywood, sheet metal, or some other substructure, and are typically referred to as pedal boards. Whenever players want to add more pedals, especially when they run out of space on a board, they must rebuild their pedal boards, which can become quite large and difficult to handle and transport.

Related Resources

It’s been a long journey with many struggles to bring my music and engineering passions together, and I needed SOLIDWORKS tools to bring me home.

With the Infinity Pedal Module, players can easily add pedals and the underlying structure via a modular slide- and snap-in cantilever beam approach,” AKASH explains. “Guitarists can keep expanding their boards quickly and easily by connecting the pedal (part A) with the substructure (part B), which then connects to the board. SOLIDWORKS has been a big part of helping me achieve this goal.”

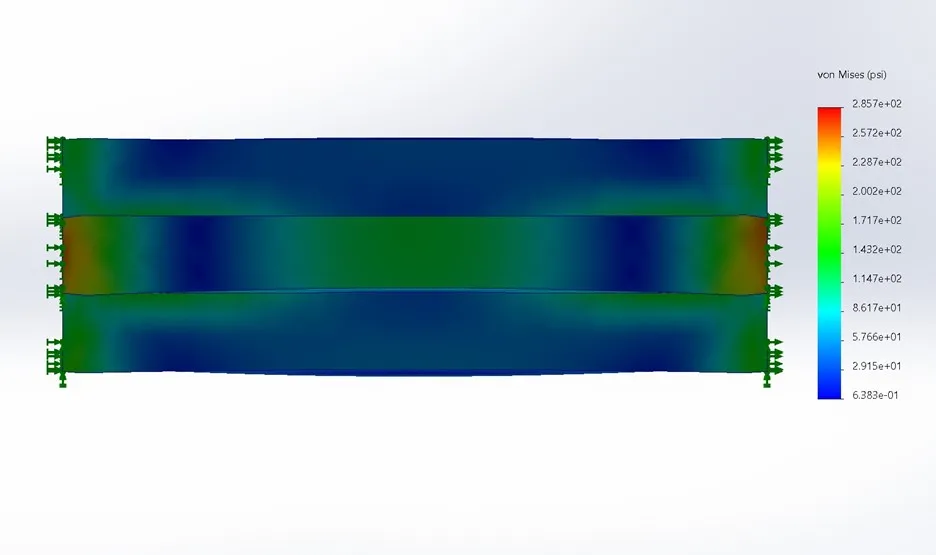

Validating Design Performance

In addition to leveraging SOLIDWORKS 3D CAD tools, 52 Sounds tapped the static analysis capabilities of SOLIDWORKS Simulation to validate and ensure that its modular pedals would perform as designed. “Pedal boards get stomped on by players of all sizes,” AKASH points out. “When you’re on the road on tour, a pedal board can take a lot of abuse.” He continually emphasized the need for rigidity and structural soundness in his Infinity Pedal Module pedal board components both individually and when connected so players can rely on them while on tour.

SOLIDWORKS static simulation, combined with the ability to use additional computing cores in the cloud for faster results along with rapid prototyping accelerated development and improved the Infinity Pedal Module’s durability. AKASH adds, “In developing these [Infinite Devices] products, I’ll be making greater use of SOLIDWORKS Simulation solutions moving forward.”

3D Printing Success

Because he had experience operating a fabrication lab during college at the University of California, Irvine, AKASH was able to form a partnership with the Sante Fe Business Incubator to get its Archimedes Fab Lab restored and up and running. Using 3D printers, 52 Sounds has already begun producing the company’s modular pedals more cost-effectively than it could with traditional manufacturing processes.

“By taking on private engineering contracts, 52 Sounds was able to self-fund its manufacturing needs and acquired six 3D printers to start production of Infinity Pedal Modules, which will be made with thermoplastic filament, and began filling orders in May 2025,” AKASH notes. “It’s been a long journey with many struggles to bring my music and engineering passions together, and I needed SOLIDWORKS tools to bring me home.”

- SOLIDWORKS for Startups

- SOLIDWORKS Simulation

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Work

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.