Sub-Zero Powers Premium Appliances with Integrated Design

Home appliance innovator eliminates rework, accelerates design cycles, and ensures product quality with SOLIDWORKS Design and SOLIDWORKS Electrical.

Challenge

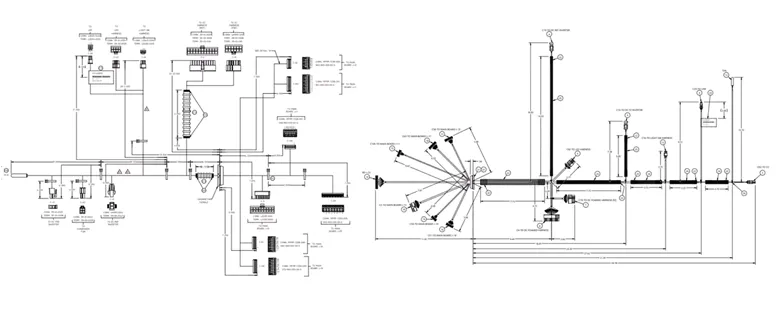

Replace manual, error-prone legacy process for creating electrical schematics, wire harness models, drawings, and wiring diagrams for premium kitchen appliances with a more efficient, error-free, automated process through a seamless, integrated connection between 2D electrical schematics, 3D mechanical models, and 2D mechanical drawings.

Solution

Add SOLIDWORKS® Electrical Schematic Professional and SOLIDWORKS Electrical Professional solutions to its existing SOLIDWORKS installation.

Results

- Shortened electrical design cycles

- Simplified flattened configurations and cut material costs

- Eliminated first-build revisions and rework

- Automated generation of BOM and wire tables directly from electrical schematics

Founded in 1945 Sub-Zero Group, Inc. has set the standard for premium refrigeration, cooking, and dishwashing appliances under the Sub‑Zero®, Wolf®, and Cove® brands. Known for craftsmanship, performance, and timeless design, the company has always sought better ways to turn visionary kitchen concepts into reliable, beautiful products. Sub‑Zero’s recent adoption and integration of SOLIDWORKS Electrical solutions with its existing SOLIDWORKS 3D design environment has transformed how its engineers work.

Manual Processes Slowed Progress

Before adopting SOLIDWORKS Electrical, Sub‑Zero’s electrical design team relied on a disconnected and cumbersome design process. Sub‑Zero engineers would draft schematics in Visio®, AutoCAD®, or SOLIDWORKS 2D and then manually translate that data into wire tables, bills of materials (BOMs), and hand-drawn harness layouts. These documents were later accompanied by a sketched 3D model that lacked detail and had no live link to schematics.

Senior Designer Isaac Semrow recalls the frustration: “The legacy process that we used to develop electrical schematics, route wiring throughout an appliance, design wiring harnesses, and create BOMs was a manual, disconnected process that took [too many] weeks.” Lead Design Engineer Jared Norgal adds that the problems were rooted in inefficiency. “Because of the manual nature of this process, it was not only slow and tedious but also prone to error, resulting in unexpected revisions, rework, and material costs.”

The company needed a more efficient, accurate, and integrated method for electrical design, one that could keep pace with the premium market’s demands for quality and innovation.

Related Resources

The complete schematic data is added to the wire harness function within SOLIDWORKS Electrical, and the schematic items are associated to the SOLIDWORKS mechanical model through association or insertion. The BOM and wire table data are automatically generated and inserted into SOLIDWORKS Mechanical to quickly and easily generate SOLIDWORKS Mechanical 2D drawings.

One Integrated System

To address these challenges, Sub‑Zero added SOLIDWORKS Electrical Schematic Professional and SOLIDWORKS Electrical Professional to its existing SOLIDWORKS installation. This strategic decision leveraged a common system to seamlessly link schematics, 3D mechanical models, and 2D drawings. Companies that adopt such integrated tools minimize redundant work, reduce errors, and enable true collaboration between disciplines, according to Dassault Systèmes’ research on MCAD and ECAD collaboration.

This integrated approach transformed Sub‑Zero’s workflow. Every element of the electrical schematic—symbols, connections, and metadata—now directly informs the 3D wire harness model, wiring diagram packages, BOMs, and wire tables. The same schematic drives all downstream tasks, eliminating any manual duplication of effort. “Each location in the schematic contains the symbols, connections, and metadata needed to create a wire harness model in SOLIDWORKS mechanical design software,” Norgal explains. “Then, the same schematic is leveraged to create a wiring diagram package, which accompanies every product to support field service.”

Faster Design Changes and Better Coordination

The impact on design turnaround has been dramatic. Electrical design cycles are shorter, revisions are handled quickly, and first-build rework has been eliminated. Instead of engineers spending weeks reconciling separate documents, a change made in a schematic now automatically cascades through the wire tables, drawings, and harness designs.

The most significant cultural change has been the improved coordination between mechanical and electrical engineering teams. Historically, those disciplines worked sequentially, leading to clashes late in the process. With SOLIDWORKS the workflow is concurrent and collaborative. Electrical schematics are linked directly to 3D mechanical models. Routed harnesses reveal true space claims and prevent the illusion of wide-open areas, which help engineers catch interferences early. Manufacturing engineers have gained detailed visibility into harness routing during design, giving them the opportunity to suggest improvements before assembly begins.

Semrow highlights the payoff: “The BOM and wire table data are automatically generated and inserted into SOLIDWORKS mechanical to quickly and easily generate 2D drawings.” This seamless flow of information ensures that every team is working from the same, most up-to-date data, dramatically reducing the chances of error.

One-Vendor Integration

Beyond speed and coordination, Sub-Zero values having a single trusted vendor in Dassault Systèmes SOLIDWORKS. Instead of juggling multiple disconnected tools, the engineering team works with an advanced technology vendor where modeling, simulation, and documentation all connect without manual transfers or rework. This built-in interoperability reduces errors, improves data integrity, and keeps every discipline working in unison. Sub Zero also benefits from the reliability of end-to-end support through their dedicated SOLIDWORKS reseller, which gives engineers the confidence that their tools are backed by deep technical expertise and long-term stability. This unified environment eliminates the risk of gaps between tools and ensures that innovation isn’t slowed by software incompatibilities or finger-pointing between vendors. Sub‑Zero’s engineers can now focus on product innovation rather than troubleshooting disconnected workflows.

Speed, Quality, and Confidence

Since adopting SOLIDWORKS electrical tools, Sub‑Zero has seen measurable improvements: significantly shorter electrical design cycles, lower material costs thanks to more accurate wire lengths, and elimination of costly first-build rework. In addition, routed harness models provide better visibility into design realities, leading to improved manufacturability assessments. And because electrical data is represented accurately in CAD, simulation and airflow analyses are more reliable, which further boosts product quality.

When mechanical and electrical teams work together with a single system, they deliver higher quality products to market faster and with fewer errors. By leveraging SOLIDWORKS, Sub‑Zero has the confidence and capability to keep creating cutting-edge innovations while delivering the timeless kitchen appliances their customers demand.

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.